June 16th

I

had a good go at the driveshafts this evening. It started off by mounting the left hand

stub axle and hub, and then assembling the driveshaft (what Westfield call a barshaft, which seems a slightly odd

name to me). There are CV joints of the type referred to as Lobro joints at either end of the bar shaft. (What

are/is Lobro? I thought it might be the manufacturer but mine were made by GKN.)

I

had a good go at the driveshafts this evening. It started off by mounting the left hand

stub axle and hub, and then assembling the driveshaft (what Westfield call a barshaft, which seems a slightly odd

name to me). There are CV joints of the type referred to as Lobro joints at either end of the bar shaft. (What

are/is Lobro? I thought it might be the manufacturer but mine were made by GKN.)

There was a bit of a problem working out which way round the joints went. On phoning Chris Masters it seems that the real giveaway is that you can only get the circlips in one way round. Pity it doesn't say that in the build manual.

The biggest problem was not having seventeen hands. I had real difficulty holding the shaft which had grease all over the place from the packed bearings at the same time as lining up the bolts at the same time as not allowing the joints to fall to bits. (I have this horror of having to chase up all the ball bearings again and work out how to put it back together.)

I'm pretty sure that it's best to dismantle the upright from the top wishbone before attaching the driveshaft to the stub axle, as otherwise it doesn't seem possible to get the shaft in. Finally, I managed it and it looks like the photo here.

One issue was the clamps on the rubber gaiters around the Lobro joints. They were real buggers to fit, I assume that real garages have some special tool for doing them up. At the end of it, they didn't exactly seem tight anyway.

One issue with all this is the hub nuts. These are big things, needing a 41 mm socket to tighten them, and are handed: left hand thread for the left of the car. The problem is the tightening torque is 250 lbf ft, which is way beyond the capacity of my torque wrench. What's more, my local tool hire place doesn't hire out torque wrenches due to the difficulty of calibrating them. Unless I think of anything better I'll have to do them up when the time comes--when the car is on the ground--by standing on a long spanner at the appropriate point.

The first thing to do is to probably phone around all the tool hire places, of which there are several.

I

then moved onto the right driveshaft, which is slightly longer than the left. (It's actually interesting how asymmetric

the car is. For example, the driver's side footwell is wider than the passengers.)

I

then moved onto the right driveshaft, which is slightly longer than the left. (It's actually interesting how asymmetric

the car is. For example, the driver's side footwell is wider than the passengers.)

This time I knew what I was doing better and decided that I should avoid packing the outer Lobro joint until I had the inboard side connected and bolted up. What's more, I knew in advance that I should disconnect the top wishbone.

Everything went fine until I went to attach the right stub axle, and hold it in with the hub nut. After fiddling with it for a few minutes I realised that the stub axle had a left hand thread. In other words, I had two left stub axles and no rights. (Although I do have the correctly handed hub nuts.)

This means the work stopped--it was too late anyway--with the driveshaft looking like this; held up with bungee straps! It seems another call to Westfield is in order.

If

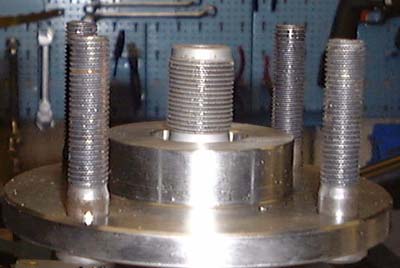

you look at this photo, which shows the end of the stub axle and the four wheel bolts, you can clearly see the

left hand thread.

If

you look at this photo, which shows the end of the stub axle and the four wheel bolts, you can clearly see the

left hand thread.

I'm getting a bit fed up with this. So far, there have been several missing fasteners, when the stuff was being put in the van at Westfield they initially gave me three front springs and one rear, I have two small brackets for the steering rack and now this.

Westfield's parts lists look fine, it seems their ability to actually pick the correct parts is not too high.

June 17th

Westfield phoned this morning to say the engine will be available tomorrow. I spent some time arranging a van to get there and an engine hoist to get the thing out of the van and into the garage. Finding a van was incredibly difficult, as just about everything in Cambridge is booked up. One of the places I phoned said it was because there were lots of parents taking their kids down from University. Seems rather odd though.

I also told them that I needed a different stub axle. I was amazed to be offered either that or another left hand thread nut! The reason for having the threads handed in this way is to stop them undoing while the car is going along. Hence having two left-handed stub axles would be a very bad idea. It was the storesman who offered me this, I hope he's not involved in the design.

in case you've got to this frame directly and can't get out, go here