As I said I hoped I would last time, I have managed to get around to painting rubbery stuff

on the inside of the wheel arches. The stuff I've got (carlife Rubbercoat) is horrible and seems to get everywhere.

What's more, it's either not going off or it takes ages to go off. Hopefully it's the latter. Unfortunately, quite

a lot of what I painted on appears to have run off again and landed on the floor, as in the photo. It's just that

it took a long time to do it.

As I said I hoped I would last time, I have managed to get around to painting rubbery stuff

on the inside of the wheel arches. The stuff I've got (carlife Rubbercoat) is horrible and seems to get everywhere.

What's more, it's either not going off or it takes ages to go off. Hopefully it's the latter. Unfortunately, quite

a lot of what I painted on appears to have run off again and landed on the floor, as in the photo. It's just that

it took a long time to do it.

While the car is in this position, I started trying to adjust the pedals a bit. In order to move the clutch pedal I cut a small amount (about 10mm) off the actuator rod of the clutch slave cylinder. That should give me room to adjust that pedal a bit. What I really need to do, though, is to move the throttle pedal a bit further away, which would mean I could heel-and-toe. I need to think a little harder about that one.

I also adjusted the choke cable a bit.

All of this finally means I've made fractional progress on the to-do list. About time too..!

Inevitably, my restarted progress ground to a halt fairly quickly. Although in this case

I've got an excuse as the turbocharger in my Toyota MR2 bit the dust and I spent last weekend taking the thing

out. The access in the engine compartment of the MR2 is just about non-existent and the Rush is dead easy in comparison.

Inevitably, my restarted progress ground to a halt fairly quickly. Although in this case

I've got an excuse as the turbocharger in my Toyota MR2 bit the dust and I spent last weekend taking the thing

out. The access in the engine compartment of the MR2 is just about non-existent and the Rush is dead easy in comparison.

I've had a bit of a problem recently with the engine not pulling properly at high revs. I'm not sure what this high speed "misfire" is but I thought I'd check a few things. First up was checking the fuel pressure which seemed a bit low at about 2psi. I would up the regulator to about 5psi which is within the range specified for the carb.

I also spent a while checking the timing, which I was aware that I might have disturbed a while ago.

The end result of that was that things seemed to be working a bit better, although only time will tell.

I've had a problem with the engine for some time now and I decided to have a go at it now. (I have

finally got the MR2 back together; at least putting it back together was a bit easier than taking it to bits.)

I've had a problem with the engine for some time now and I decided to have a go at it now. (I have

finally got the MR2 back together; at least putting it back together was a bit easier than taking it to bits.)

The problem is that when I start the engine after it's been left for more than about 4-5 hours, then there's a rather a "tappety" sound coming from one of the heads. This goes away, after the engines warmed up but I've been wondering about opening up the engine and having a look. One possibility is that one of the hydraulic lifters is not working too well.

I want to take things to bits anyway as I've bought an oil cooler, as in the photo, and need to work out where to fit it. This isn't going to easy and I probably need to take the radiator out to get at things.

So, I set about the engine and took the carburettor off and the the inlet manifold

and the associated gubbins, until I had exposed the lifter gallery and the set of valve gear that's clicking. Perhaps

disturbingly everything looks OK. One possible approach is just to try changing the lifters and see what happens.

A friend has a set of Rhodes lifters which he's not using. That would at least allow me to try it and see. Rhodes

lifters are special lifters which are designed to "bleed down" at low rpm which essentially alters the

low rpm valve timing and produces more torque at low rpm. However, they have a reputation for making the engines

a bit more noisy, which may not be such an issue for me.

So, I set about the engine and took the carburettor off and the the inlet manifold

and the associated gubbins, until I had exposed the lifter gallery and the set of valve gear that's clicking. Perhaps

disturbingly everything looks OK. One possible approach is just to try changing the lifters and see what happens.

A friend has a set of Rhodes lifters which he's not using. That would at least allow me to try it and see. Rhodes

lifters are special lifters which are designed to "bleed down" at low rpm which essentially alters the

low rpm valve timing and produces more torque at low rpm. However, they have a reputation for making the engines

a bit more noisy, which may not be such an issue for me.

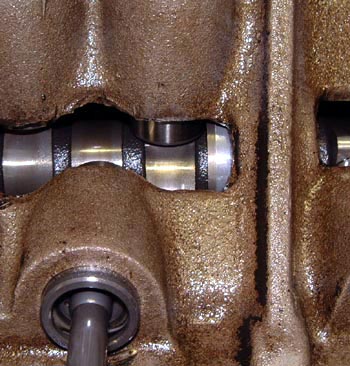

However, on closer inspection there is a bit of an issue. When I rebuilt the engine ages ago I had some new camshaft bearings pressed into the block. I realised that I could see one of these down at the bottom of the lifter gallery, meaning that the bearing has moved slightly. Perhaps I should have left the old bearings in...? You can see the bearing in this photo here, just to the right of the cam lobe in the middle of the picture.

Problem is, I'm not sure what to do. I could take everything to bits and try and get the bearing back into position. Presumably though, that shouldn't be possible without taking the engine to bits and using a socking great press. If I could do it with anything less then doesn't that mean it would just move again? I could just assume that this is where it wants to be and leave it alone. (It could just be that it was always like this. I've had a look through all the past photos but can't find anything that's clear enough to see.) Hmmm, any suggestions gratefully received.

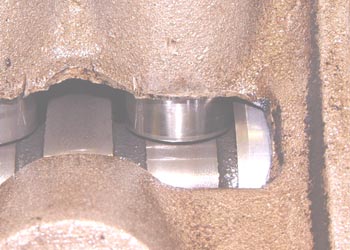

I had a bit more of a look at the camshaft issue today. I realised that in the

photo above, the follower was lifter up so I move the engine round so that the follwer was sitting on the cam lobe's

base circle. The photo here is in that position (and filtered so that you can see properly.) As you can see it

looks as if the bearing is just about touching the side of the follower. In fact, it's possible that the tappet

rattle is coming from here?

I had a bit more of a look at the camshaft issue today. I realised that in the

photo above, the follower was lifter up so I move the engine round so that the follwer was sitting on the cam lobe's

base circle. The photo here is in that position (and filtered so that you can see properly.) As you can see it

looks as if the bearing is just about touching the side of the follower. In fact, it's possible that the tappet

rattle is coming from here?

After discussing this a bit with people on the dax mailing list I decided I was going to at least have to take the camshaft out. Apparently it is possible to whack the bearing back into position without taking the crank out. Someone else, though, pointed out that if the bearing had rotated then it could have blocked an oil feed which would perhaps explain the noise.

Given all that it seems like I am going to have to remove the cam shaft, so

I set about it. Obviously, the radiator will need to come out to provided access from the front so that was the

first thing to remove. I didn't have too much time but in a fairly short while I had got down to this. Next I'll

remove the water pump and engine front cover and I won't be far from the camshaft then... Obviously, while I'm

at it I'll at least be able to look into fitting the oil cooler and perhaps do a bit of tidying up...

Given all that it seems like I am going to have to remove the cam shaft, so

I set about it. Obviously, the radiator will need to come out to provided access from the front so that was the

first thing to remove. I didn't have too much time but in a fairly short while I had got down to this. Next I'll

remove the water pump and engine front cover and I won't be far from the camshaft then... Obviously, while I'm

at it I'll at least be able to look into fitting the oil cooler and perhaps do a bit of tidying up...

in case you've got to this frame directly and can't get out, go here.