Good Grief! I managed to get through all of last month without actually updating this site. Sorry about

that, especially all you impatient people who've kindly written to me and complained...

Good Grief! I managed to get through all of last month without actually updating this site. Sorry about

that, especially all you impatient people who've kindly written to me and complained...

In the meantime you might be worried that the font I'm using has shrunk. It hasn't really, it's just that I got fed up allowing for a well-known bug in Internet Explorer and just started using proper sizes. If you don't like it just increase the size on your machine. (On a modern PC this is most easily achieved with control-mousewheel.)

Alternatively start using Firefox as an increasing number of visitors to this site do.

Right, enough of the IT stuff. Problem is, it's the IT stuff that's been preventing me updating the site, just due to lack of time. I have, though, still been creeping forwards. I must admit, though, that getting everything done that I talked about a while ago is a complete pipe-dream.

So, what has happened? The cliff-hanger at the end of the last episode was a photo of the engine sitting in its cradle waiting to go off to Andy to have a poke around in the internals. That's been done now. I don't have it back yet although I'm expecting it in the next week or so.

As discussed a while ago. I've spent a while experimenting with carbon fibre panels to replace some of the aluminium. The main reason for getting into this in the first place was just to have something different to replace the dash with. However, I got a little carried away. Needless to say, learning how to use carbon fibre is not easy but I'm getting there. Presently I'm just sticking to flattish panels and using wet-layup and using weights for consolidation. Some friends keep insisting that I should be vacuum-bagging things and they're probably right in the long run. However, for now it's taken long enough to sort out simple wet layup.

As part of this, I've replaced the entire top of the tunnel with carbon-fibre/epoxy panels, as in the photo. The fact that the patterns on the bit nearest the camera and the next furthest one away match up so well is, of course, a complete fluke. Neat though...

While you're marvelling at my skills by looking at that photo cast your eyes up to the reversing lever. Something I've been meaning to do for a while is to shorten this, and possibly put some sort of blunt handle on it. I put it together ages ago when I build the car after the first attempt was a failure. I've been meaning to sort it ever since and never got around to it. I'll try and do something better soon, perhaps in concert with moving the actuation button to the side of the lever.

Something

else that I mentioned a while ago was getting some lighter dampers. Despite the howls of protest from some quarters

I decided that I'd give the Protech dampers a go. If they turn out to be no good I can easily take them off again.

Something

else that I mentioned a while ago was getting some lighter dampers. Despite the howls of protest from some quarters

I decided that I'd give the Protech dampers a go. If they turn out to be no good I can easily take them off again.

In the meantime they certainly look the business and are indeed considerably lighter than the steel-bodied AVOs that I've taken off the car. As you can see, they've also got spherical bearings on the end of them rather than the bushes that the current ones have. I guess that means the car's going to get even more rattly from now on!

Another

suspension related thing was getting some roller bearings for the front rocker arms. These replace the rather nasty

"steel rod in a plastic bush" things that are standard on the car. When it came to fitting these it took

a while to get the old ones out. However, when I did...

Another

suspension related thing was getting some roller bearings for the front rocker arms. These replace the rather nasty

"steel rod in a plastic bush" things that are standard on the car. When it came to fitting these it took

a while to get the old ones out. However, when I did...

...it

became obvious that replacing them had been a good idea. As you can see, the old rod is really rather rusty and

had ground away at the inside of the original bush a good deal. The only problem with the new ones is that I suspect

they're going to need a bit of looking after. In particular, I think I'll have to take them apart every year to

clean and regrease them.

...it

became obvious that replacing them had been a good idea. As you can see, the old rod is really rather rusty and

had ground away at the inside of the original bush a good deal. The only problem with the new ones is that I suspect

they're going to need a bit of looking after. In particular, I think I'll have to take them apart every year to

clean and regrease them.

One problem was, though, that the new bearings are designed for the new Fury chassis. This is set up to allow the rockers to be moved fore and aft so as to allow the caster to be changed which means it's easier to set the steering up in such a way that the SVA test can be passed. In my case this adjustment is not present and I had to cut down the bearing rods a bit. I took a good deal of car about this, including making a small jig so that I could grind the ends of the bearing rods properly square using my bench grinder.

So,

with those two things I can start putting the suspension back together. This photo has the rocker mounted with

the bearings and with the new damper in situ. In doing this I realised that as a consequence of having the rod

ends on the ends of the dampers, I'll need some more side spacers so as to stop the damper moving about in the

mountings. I ordered from of these from Rally Design this morning.

So,

with those two things I can start putting the suspension back together. This photo has the rocker mounted with

the bearings and with the new damper in situ. In doing this I realised that as a consequence of having the rod

ends on the ends of the dampers, I'll need some more side spacers so as to stop the damper moving about in the

mountings. I ordered from of these from Rally Design this morning.

Another suspension thing that I wanted to do was to remake the rear upper wishbones. With the suspension set up in the usual way although the current ones are OK, I'd be happier if the upper rodends were just a little more inside the threaded bushes in the wishbones.

Hence,

I've modified the jig that I made last year for the wishbones so that the outer mounting is a few millimetres further

out. After reclaiming the tube notcher from Dan I've started remaking these components. I'll keep the old ones

for spare in any case.

Hence,

I've modified the jig that I made last year for the wishbones so that the outer mounting is a few millimetres further

out. After reclaiming the tube notcher from Dan I've started remaking these components. I'll keep the old ones

for spare in any case.

The photo here shows the first such remake. It's only tacked together at the moment though but you get the idea. With luck I'll make the other one soon. As in all these things, the process of actually welding the parts together is quite easy, it's all the measuring and cutting before hand that's tricky. In this case, notching the tubes is a pretty tedious.

I've been looking at the race diary for this year and I've realised that I really need to get my skates on to get the car back together. Hence, I suspect that some of my more grandiose ideas will get binned. The biggest thing that I do have to do, though, is to make the new dash and finish the new Palm software. I've mocked up the latter but the code actually needs writing now. I've ordered just about enough bits so that I won't have to cannibalise the old dash, just in case I really do run out of time.

Crikey,

he really has got skates on! That's two updates in less than, errrrm, two weeks!

Crikey,

he really has got skates on! That's two updates in less than, errrrm, two weeks!

Anyway, my attention now turned to the front of the car. There's a couple of things I need to do here. I want to essentially rebuild the steering system to try and make it work a bit more smoothly and get rid of some annoying play in the various couplings. I also want to move the radiator slightly, hopefully so as to allow better airflow, and also to clear a channel, should I need it, for a more sophisticated carburettor air intake.

So I took everything apart and ended up with the front end of the car looking like this. I also adjusted the rack mounts slightly so as to square them up: when I got the front end of the chassis replaced ages ago the pillocks that welded the new bit together clearly aligned the rack mounts using a lump of BluTack and a bent plumb line. I adjusted the rack mounts carefully with the proper mount adjuster. I think it was the 5lb club adjuster.

So, after a lot of faffing around, the front end of the car looked like this. Eagle eyed readers will

note the tiewraps that are holding the front suspension up, I'll take them off later, honest.

So, after a lot of faffing around, the front end of the car looked like this. Eagle eyed readers will

note the tiewraps that are holding the front suspension up, I'll take them off later, honest.

The rack here is actually a brand new item. For some reason they're surprisingly cheap and I've always worried that the rack was fine after some of the punishment that I've given it. Essentially this now means that I've got a spare.

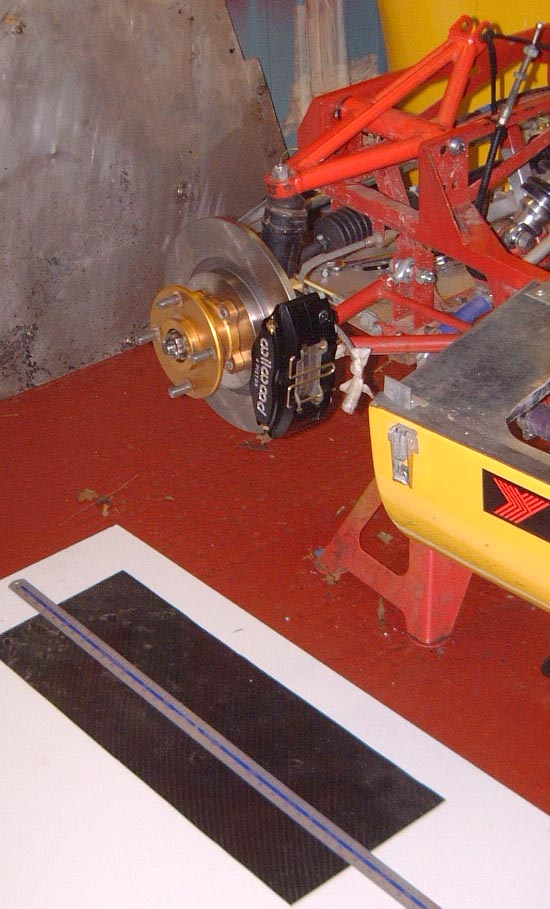

As

part of putting the front suspension I took a good deal of care fitting the rosejoints properly. This was also

the first time that the new brakes went onto the car. They certainly look rather more chunky than they used to.

As

part of putting the front suspension I took a good deal of care fitting the rosejoints properly. This was also

the first time that the new brakes went onto the car. They certainly look rather more chunky than they used to.

Once all this was together I did something I've been meaning to do for ages and checked the bumpsteer which is why there's a ruler sitting on a spare bit of carbon fibre on the ground in this photo. Following a suggestion made by Carroll Smith in one of his books it's quite easy to check the bump steer by squinting vertically down and aligning the flat plate of the wheel hub with the ruler on the ground and moving the suspension up and down. (You'll notice in this photo the suspension unit itself has been disconnected.)

After a certain amount of faffing about with spacers around the rack mounts and a little more adjustment it was pretty good. In fact, it was as good as I could tell.

With

that done I now want to basically make a new steering column using proper components rather than the nasty old

Sierra column I had before which has really horrible, horrible bearings in it. I'm hoping that after this there

won't be a smidgeon of play anywhere in the steering. (It'll probably vibrate my hands to pieces...)

With

that done I now want to basically make a new steering column using proper components rather than the nasty old

Sierra column I had before which has really horrible, horrible bearings in it. I'm hoping that after this there

won't be a smidgeon of play anywhere in the steering. (It'll probably vibrate my hands to pieces...)

There's a number of components that are going to go into the column. Firstly there's a new Racetech steering wheel adapter. I turned down the adapter shown here by about 0.5mm to fit snugly inside some CFS tubing that I'll use for the column itself. The problem with these adapters is that they're dead expensive (about £100) and come in matched pairs that you have to keep together properly.

Later on I'll weld and pin (as recommended by Racetech) the adapter on the right into the column tubing.

That tubing will have these sleeves fitted around it. I bored these out (well, Dan did as it was his

lathe) so as to fit snugly around the upper column tubing. Later on I'll weld them into place.

That tubing will have these sleeves fitted around it. I bored these out (well, Dan did as it was his

lathe) so as to fit snugly around the upper column tubing. Later on I'll weld them into place.

Hopefully in such a way that they'll still slide in and out of these bearings which are sealed units

which should work fine in the grotty environment of a race car. These bearings fit into housings, you can see a

bit of one at the top left of the photo, that I'll mount onto bracketry on the car.

Hopefully in such a way that they'll still slide in and out of these bearings which are sealed units

which should work fine in the grotty environment of a race car. These bearings fit into housings, you can see a

bit of one at the top left of the photo, that I'll mount onto bracketry on the car.

The

upper and lower column will be joined by this high quality UJ, also from Racetech at an alarming price. Again,

this fits snugly into the column seamless tubing.

The

upper and lower column will be joined by this high quality UJ, also from Racetech at an alarming price. Again,

this fits snugly into the column seamless tubing.

At the bottom of the column I'll weld this gadget in, which is made from a chunk of a standard Escort

steering column with a machined sleeve that also fits snugly (actually too snugly) into the tubing.

At the bottom of the column I'll weld this gadget in, which is made from a chunk of a standard Escort

steering column with a machined sleeve that also fits snugly (actually too snugly) into the tubing.

That

is finally attached to the rack using this "Group 4" coupling which is a replacement for the truly horrible

"rubber disc" thing that the car had before. As I said, it'll probably provoke the carpal tunnel syndrome

in my wrists something horrible...

That

is finally attached to the rack using this "Group 4" coupling which is a replacement for the truly horrible

"rubber disc" thing that the car had before. As I said, it'll probably provoke the carpal tunnel syndrome

in my wrists something horrible...

Finally,

I made another carbon fibre panel, in this case for the end of the passenger footwell. I did this one now because

Andy phoned me at the weekend to tell me that my engine would be available for collection at the beginning of this

week. This panel is inaccessible once the engine is in so if I'm going to replace it I need to do it now.

Finally,

I made another carbon fibre panel, in this case for the end of the passenger footwell. I did this one now because

Andy phoned me at the weekend to tell me that my engine would be available for collection at the beginning of this

week. This panel is inaccessible once the engine is in so if I'm going to replace it I need to do it now.

So I did...

By the way, note the cool reflections...

Well, the slow progress continues but I am slowly getting somewhere. I've sent in my registration for

the 2007 series and I suppose I should really read the new regs some time! I still don't have my 2007 licence back

but I've just checked the MSA site and they do now admit to starting processing my application so hopefully it'll

be back soon.

Well, the slow progress continues but I am slowly getting somewhere. I've sent in my registration for

the 2007 series and I suppose I should really read the new regs some time! I still don't have my 2007 licence back

but I've just checked the MSA site and they do now admit to starting processing my application so hopefully it'll

be back soon.

In the meantime the car itself has been moving forwards slowly. I've now got the steering column parts all ready. I haven't actually done any pinning or welding yet as I want to think for a while before doing anything irreversible. I've only got this far because muggins here had bought the wrong size UJ and had to buy a new one. Sigh. The nice thing about this new column is that it really does seem to have next to no play in it and to turn rather more smoothly than the old one.

Next thing to do is to make up some sort of bracket to which the gearchange lever can be bolted. Previously it clamped around the outside of the column. This isn't now possible as there isn't a shroud round the column. The current plan is to make some sort of aluminium bracket and bolt the adapter to the bracket that supports the upper column bearing. I really ought to remake that bracket as it's a bit on the studly side being made of 3mm steel. However, things are a bit rushed at the moment. I might add some lightness with the aid of a holesaw.

I've also made up some new flexible pipes for the new front brakes. I have a feeling that they're a bit long though so I'll probably redo them.

I got the engine back from Andy last week, along with a new airbox. However, I've discovered a problem and it's had to go back to Andy. He says he'll have it back to me this week which would be good as once I've got the engine back in I can start sorting the new dash and so on. I must admit, this is all starting to feel a bit pressured. However, the first race of the season is at Mallory and given my past record there (three visits, two crashes, one blown engine) I just might give it a miss this time. Be a shame to lose the points though.

Yet

again, too little progress to report. At this rate I'm just going to miss the first meeting.

Yet

again, too little progress to report. At this rate I'm just going to miss the first meeting.

First thing this weekend was to make the gearchange work. In order to do this I had this little chunk of billet aluminium made for me. That sounds rather pompous but essentially I did a CAD drawing of what I wanted and emailed it and the CNC files that the CAD package generates off to a friend who teaches at a local Further Education college. They've got lots of fancy kit there and he actually got a student to make this up as a piece of class work. (I paid for the chunk of aluminium.) It's not exactly complicated though in that it's just a cuboid with a ramp milled off the top and some tappings in it.

However,

ones bolted in place it allows the gearchange to be held in position like this.

However,

ones bolted in place it allows the gearchange to be held in position like this.

I have to admit to being slightly wary about all this as the gearchange is now connected to that cross piece that supports the column. This lump of steel is proverbially flexible on the Fury and I'm a little concerned that any flexing could affect the steering. However, I doubt it's a big deal and I'll do some careful tests later.

At least for now all this lot is together, although I still haven't done the welding and pinning that's necessary to hold the column together at the moment. Right now there are two small problems: twirling the wheel doesn't move the front wheels and pulling the steering wheel means the column falls off and lands in your lap. Apart from that it's perfect...

Still,

ignoring that problem I also got stuck in and made the new dash. The fundamental difference here is that I'm now

dependent on the Palm and I've tried to remove everything unnecessary. For example, last time I included a hazard

flasher reasoning that that was needed to pass an MOT. However, in retrospect that's isn't really true as it's

only needed for new cars not in general. So, I've left it off. This is in the same vein as the fog light which

I didn't have before, as the same reason occurred to me late in the day. Hence, did have a switch on the dash for

it, but no light on the back of the car. What I do have, of course, is the required rain light which is quite like

a fog light but positioned in a place on the car which wouldn't be acceptable for a fog light.

Still,

ignoring that problem I also got stuck in and made the new dash. The fundamental difference here is that I'm now

dependent on the Palm and I've tried to remove everything unnecessary. For example, last time I included a hazard

flasher reasoning that that was needed to pass an MOT. However, in retrospect that's isn't really true as it's

only needed for new cars not in general. So, I've left it off. This is in the same vein as the fog light which

I didn't have before, as the same reason occurred to me late in the day. Hence, did have a switch on the dash for

it, but no light on the back of the car. What I do have, of course, is the required rain light which is quite like

a fog light but positioned in a place on the car which wouldn't be acceptable for a fog light.

I had a phone call today from Andy to say that the engine will be done tomorrow. Problem is, I've no idea when I'm going to be able to find the time to go out to wilds of deepest darkest Suffolk to get it back... I won't be able to fit it just yet. The priority in the short term is to do the dash wiring. Although it might look OK in that photo above there's a complete absence of wires on the back...

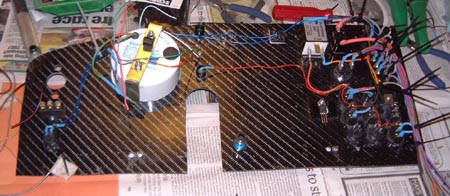

Just

to emphasise the point I've decamped to the dining room table to do the dash wiring, as in the photo. There's an

awful lot of it to do yet.

Just

to emphasise the point I've decamped to the dining room table to do the dash wiring, as in the photo. There's an

awful lot of it to do yet.

I booked a track day yesterday in Snetterton on Feb 24th. I hope I can get the car back together by then, but it's going to be close run thing. To get me on the way the engine should be coming back to me tomorrow. Luckily Andy's got to go to Dunstable so he's almost passing my house.

I've also got all the stuff now for putting in my entries for the RGB races this season. The first one is supposed to be at Mallory on March 11th which I suppose I ought to do, despite my appalling record at Mallory. As I know my licence is on the way back now I'll get the entries put in. I got a rather odd "temporary licence" in the post today. I assume that this is because the MSA haven't managed to get the proper licence done so they've issued the temporary one until they can send me the real one. I suppose the other possibility is that they've run out of Blue Books...