I braved the cold and ventured into the garage. The autumn leaves are blowing under the garage door again which makes the whole place less attractive somehow...

The first thing was to modify something. There's been some discussion on the

mailing list about the duff throttle pedal mounting that Dax use. I made sure that mine wasn't going to tighten

up in use and leave me with a car stuck with an open throttle. This uses two nuts tightedned against one another,

a technique beloved of ex Meccano users, to ensure that it's tight, but not tight against the pedal. I hope it

works...

The first thing was to modify something. There's been some discussion on the

mailing list about the duff throttle pedal mounting that Dax use. I made sure that mine wasn't going to tighten

up in use and leave me with a car stuck with an open throttle. This uses two nuts tightedned against one another,

a technique beloved of ex Meccano users, to ensure that it's tight, but not tight against the pedal. I hope it

works...

After that, things went into a bit of a decline.

I was intending to do the other side, but I was looking at the site of the small oil leak as mentioned before. After some time I convinced myself that I really ought to investigate it as that would fit with my principle of trying to do things properly. Unfortunately, that seems to imply taking off one of the heads.

After some time arguing with myself I decided that it really had

to be done, so I set to. The inlet manifold came off after only a small struggle and left the engine looking rather

naked.

After some time arguing with myself I decided that it really had

to be done, so I set to. The inlet manifold came off after only a small struggle and left the engine looking rather

naked.

Then I took off the right hand rocker cover (on the left of this photo). Everything looked find underneath so I started to remove the rocker shaft.

"Clunk! Tinkle, tinkle!" the engine said.

"Bugger!", I said.

I couldn't see what was wrong at first so I pressed on and removed the rocker shaft. Then I looked a little harder and noticed something rather odd.

The pushrods on this engine are "heavy duty" ones from Real Steel.

Unlike the standard rods these are essentially a tube with a ball bearing welded onto each end. The problem was,

one of the balls was missing. That must have been what I heard tinkling and presumably the ball, or what's left

of it, is somewhere in the bowels of the engine.

The pushrods on this engine are "heavy duty" ones from Real Steel.

Unlike the standard rods these are essentially a tube with a ball bearing welded onto each end. The problem was,

one of the balls was missing. That must have been what I heard tinkling and presumably the ball, or what's left

of it, is somewhere in the bowels of the engine.

In fact, the end of the rod is pretty mangled, this photo shows it a bit more

clearly.

In fact, the end of the rod is pretty mangled, this photo shows it a bit more

clearly.

This left me with two problems. First of all, where is the ball and why has this happened?

I took off the valley gasket to try and find the ball and it wasn't between the heads, so the likely thing is that it's found its way into the sump. I drained the oil, and then sieved it, but couldn't find anything. Hence, I think I'm going to have to drop the sump to try and find it.

Unfortunately, I have no clue as to what can have happened. The valve associated with this rod appears to work fine, the rockers and shaft are all just about new too.

One thing that is clearly true is that this cylinder wasn't working properly. I took out the plugs and the one for this cylinder has clearly seen less excitement in its short life.

On closer inspection something else amiss turned up. The stem of one

of the other valves in this head looks markedly worn. What's more, the rocker for this valve looks as though no

oil has been flowing through it; the cup that the end of the pushrod fits in looks un-oily which doesn't seem right.

Furthermore, the bit of the rocker that bears on the valve stem is also worn.

On closer inspection something else amiss turned up. The stem of one

of the other valves in this head looks markedly worn. What's more, the rocker for this valve looks as though no

oil has been flowing through it; the cup that the end of the pushrod fits in looks un-oily which doesn't seem right.

Furthermore, the bit of the rocker that bears on the valve stem is also worn.

This is all rather depressing. I can replace these worn bits, and hopefully find the ball, but none of it explains what was wrong. The only thought is some sort of oil starvation, but there seemed to be lots of oil sloshing about when the engine was running, and quite a lot of it is still in the head, you can see some in the photo on the right.

Oh, and after all that I took the head off and nothing appeared to be wrong with the head gasket that would have caused the oil leak that started me off on this investigation.

Bugger! Anyone with any suggestions as to what to do about this can feel free to email me.

This evening I took the sump off. I had needed to buy a new socket set first,

one that was 3/8" drive rather than 1/2", as that meant I could get at the bolts at the rear of the sump.

When I put the sump on the gearbox wasn't attached so it

was rather easier to get at things. Needless to say, having got it off I put my head under the engine and got oil

in my hair, and there wasn't a ball bearing to be seen. With luck it's on top of the windage tray which I didn't

have time to take off today.

This evening I took the sump off. I had needed to buy a new socket set first,

one that was 3/8" drive rather than 1/2", as that meant I could get at the bolts at the rear of the sump.

When I put the sump on the gearbox wasn't attached so it

was rather easier to get at things. Needless to say, having got it off I put my head under the engine and got oil

in my hair, and there wasn't a ball bearing to be seen. With luck it's on top of the windage tray which I didn't

have time to take off today.

I phoned up Real Steel today and had a chat to them. Unfortunately, they don't have any real ideas what caused this either. They're sending me a replacement pushrod anyway, and I ordered a couple of other bits too, so I should be able to put it back together again.

Found it! I took off the

windage tray and there it was.

Found it! I took off the

windage tray and there it was.

Interestingly, the ball itself is just about undamaged, and only shows a little sign of having been welded to something, so perhaps it was just due to a manufacturing defect. The only issue now, then, is why the other rocker was wearing out the other valve. I think I'll put it back together and spin it round checking for oil in the required places...

Having sorted the mising ball, I set to to put the engine back together again. Needless

to say, this took rather longer than taking it apart. The oil strainer went back on with the windage tray and then

I put the sump back. It was much easier the first time I put this on because it was on an engine stand at the time.

Having sorted the mising ball, I set to to put the engine back together again. Needless

to say, this took rather longer than taking it apart. The oil strainer went back on with the windage tray and then

I put the sump back. It was much easier the first time I put this on because it was on an engine stand at the time.

Then I replaced the valve in the head that was damaged, doing some small amount of grinding to check that it fitted the seat properly which seemed fine. I reassembled the rocker shaft, using a couple of new rockers. Then I put the head back on, using a new gasket. I thought I ought to check the oil flow to the rocker shaft so I spun the engine on the starter motor to check it cam out of the feed hole. It did so, to the extent that it squirted all over my overalls...

Then the rocker shaft was put back in place and I checked that oil appeared around the rockers when the engine was turning over. Everything seemed fine, so I am left unsure as to what went wrong.

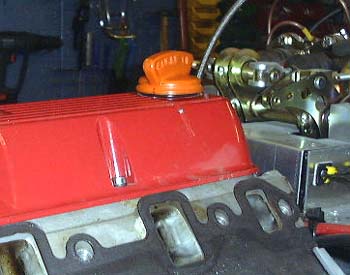

So, I put the rocker covers back, having removed the oil filler neck from one of them,

which I think would have been too high for the bonnet. I had to cut off the bottom of the filler cap to make sure

it missed the rockers on the inside after this, but it seems fine.

So, I put the rocker covers back, having removed the oil filler neck from one of them,

which I think would have been too high for the bonnet. I had to cut off the bottom of the filler cap to make sure

it missed the rockers on the inside after this, but it seems fine.

in case you've got to this frame directly and can't get out, go here.