I've done a lot of the big stuff now and I'm now trying to get the car into

a position where I should put it down on the ground and fit the engine. It's much more convenient at this height

but very inconvenient with the Dax in the garage too. I have this theory that if I could push it about it would

be easier to do things.

I've done a lot of the big stuff now and I'm now trying to get the car into

a position where I should put it down on the ground and fit the engine. It's much more convenient at this height

but very inconvenient with the Dax in the garage too. I have this theory that if I could push it about it would

be easier to do things.

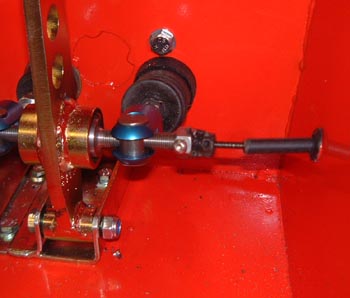

Anyway, one job to tackle is to fit the brake bias adjuster. This is essentially a cable with an adjuster knob (quite a nice bit of turned ally with a detent every half turn). On the other end there's a little gadget that fits onto the bias adjuster shaft. Although, in my case it didn't as my shaft is a UNF thread and it was set up for a metric thread. The gadget was essentially a nut of the required size welded to the sleeve into which the cable locks using a grub screw. I just angle ground off the original nut and welded a UNF one on instead. I also drilled and tapped a small hold in the side of the nut so that it could be locked to the adjuster shaft.

At the moment the adjuster cable goes straight through the side of the pedal box. I'm not at all sure how this will affect the throttle pedal which hangs down into this space from above. I can see me having to move the position later on, but that's no big deal.

The adjuster itself will end up position in the side pod to the right of the steering wheel. One of the things about the Fury, especially for those like me who have build sevenesque cars before, is getting one's head around how much space there is inside the sidepods. I had originally been thinking that the fire extinguisher would have to be positioned inside the passenger side of the tunnel. However, when looking at cars at the Kit Car Workshop last week it was obvious that there's loads of room for an extinguisher inside the sidepod, which means that the passenger position can be kept free. Mind you, it's no good for people like me as it's too short.

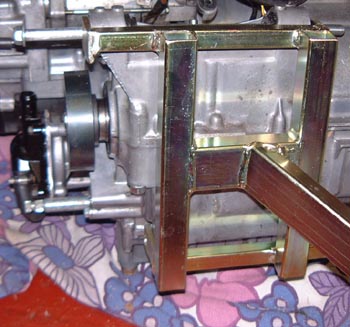

The next big thing to do is to fit the engine. So, I started looking at the engine

mountings. The Fisher supplied mountings are a fine piece of agricultural engineering, but will probably do the

job. This one here fits around the gearbox on the engine and mounts to a plate via the flange at the bottom.

The next big thing to do is to fit the engine. So, I started looking at the engine

mountings. The Fisher supplied mountings are a fine piece of agricultural engineering, but will probably do the

job. This one here fits around the gearbox on the engine and mounts to a plate via the flange at the bottom.

I think the gearbox should have two long bolts which go through both sides of this.

Unfortunately, mine's only got one which is seen here at the top. I'll need to get another

one for the bottom from a local fastener supplier. The top bolt is a strange thread in that it's M10x1.25. However,

it doesn't seem to matter too much and the bottom one will probably end up being the normal M10x1.5 as I suspect

that's all I can get. It may well be that I have to get a length of studding, but that will also be OK.

Unfortunately, mine's only got one which is seen here at the top. I'll need to get another

one for the bottom from a local fastener supplier. The top bolt is a strange thread in that it's M10x1.25. However,

it doesn't seem to matter too much and the bottom one will probably end up being the normal M10x1.5 as I suspect

that's all I can get. It may well be that I have to get a length of studding, but that will also be OK.

There's a spacer in the top mounting which holds apart some bushes. I'll have to shorten this to make everything fit properly.

Finally, I fitted the clutch cable to the clutch pedal. That's no big deal really.

You can see the cable just to the right of the brake master cylinders in this photo. Fury chassis used to have

a tube welded into the chassis here but the latest one appears to be designed for this sort of chunky nylon end

to the cable. I have a feeling that this is the same sort of cable that used to be on my Westfield, which will

mean that it's come from a Ford parts bin somewhere.

Finally, I fitted the clutch cable to the clutch pedal. That's no big deal really.

You can see the cable just to the right of the brake master cylinders in this photo. Fury chassis used to have

a tube welded into the chassis here but the latest one appears to be designed for this sort of chunky nylon end

to the cable. I have a feeling that this is the same sort of cable that used to be on my Westfield, which will

mean that it's come from a Ford parts bin somewhere.

I've realised that it would be a good idea to sort out a steering wheel so that I can get

things like the position of the wheel and pedals sorted. I'd like to get a removeable one and after much faffing

about the Racetech wheel and removeable boss seem like a good product at a reasonable price.

I've realised that it would be a good idea to sort out a steering wheel so that I can get

things like the position of the wheel and pedals sorted. I'd like to get a removeable one and after much faffing

about the Racetech wheel and removeable boss seem like a good product at a reasonable price.

What I don't really understand is what I have to chop off on the steering column. This is what the end of the column looks like,

and this is what the boss looks like. The steel stub here has to be welded to

the column directly. I assume that the top of the column should be cut off down to the hexagonal bit. I'm not sure,

yet, whether I'll try and weld this myself or get a professional to do it!

and this is what the boss looks like. The steel stub here has to be welded to

the column directly. I assume that the top of the column should be cut off down to the hexagonal bit. I'm not sure,

yet, whether I'll try and weld this myself or get a professional to do it!

I've just ordered the wheel and boss from Raceparts, who seem offer these products at a fairly competitive price. That is, not quite as mind-numbing as other suppliers

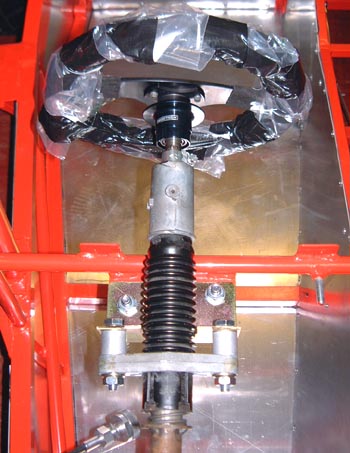

I got the steering wheel and boss today, and it's a thing of great beauty. I went for a

260mm wheel in black suede as that might be the best thing to grip when in a some sort of frantic corner.

I got the steering wheel and boss today, and it's a thing of great beauty. I went for a

260mm wheel in black suede as that might be the best thing to grip when in a some sort of frantic corner.

The wheel was a pretty good price, which is more than can be said for the removeable mounting boss which is pretty expensive.

What I need to do is to work out what I need to cut off, or whatever, to weld

the spigot to the top of the steering column. I'm concerned that I'll munge it all and end up needing another column

(not too bad) or another boss (really bad).

What I need to do is to work out what I need to cut off, or whatever, to weld

the spigot to the top of the steering column. I'm concerned that I'll munge it all and end up needing another column

(not too bad) or another boss (really bad).

Next thing today was to fit the mountings to the engine. I had got some M10

studding and made two long bolts for the gearbox-side mounting that way. The other two mountings were pretty easy

too.

Next thing today was to fit the mountings to the engine. I had got some M10

studding and made two long bolts for the gearbox-side mounting that way. The other two mountings were pretty easy

too.

Mind you, the quality of manufacture of these bits is rather duff. I even had to use a file to slot the mounting holes in this bit so that it would fit. You would have thought that Fishers would have used a jig for making things like this.

With luck I can at leat trial fit the engine over the coming weekend. Right now, I'm concerned that that oil filter is going to bash into something.

Finally, I attached the throttle pedal. I think it may well need a broader pedal surface, but then my size 12s might remove that as a problem!

With the engine mountings on, it was time to get the engine in. (Although I

suspect I'll take it out a few times.) First thing was to put the car down on the ground which was pretty easy

to do. The engine mountings leave a lot of room for freedom so I needed to trial fit the engine first so that I

could see where to drill the mounting holes. So, I marked the plates with masking tape and lifted it into position.

With the engine mountings on, it was time to get the engine in. (Although I

suspect I'll take it out a few times.) First thing was to put the car down on the ground which was pretty easy

to do. The engine mountings leave a lot of room for freedom so I needed to trial fit the engine first so that I

could see where to drill the mounting holes. So, I marked the plates with masking tape and lifted it into position.

I spent an age shoving the engine about trying to get it lined up with the diff so that the propshaft will be straight-ish. To be honest, I'm not sure I've succeeded too well and I can see me having to move it later.

All the same, I marked the positions, took the engine out again, drilled the mounting holes and then bolted the engine in properly. It's certainly very easy getting the engine in and out compared to previous kit cars, but's that's because the engine/gearbox is essentially a squarer shape than the long thing assembly of a normal car engine.

With the car on the ground and moveable (it's really light at the moment!) it's

getting easier to try things for size. So I spent a while climbing in and out with the rollcage in position, trying

to work out where the steering wheel should go.

With the car on the ground and moveable (it's really light at the moment!) it's

getting easier to try things for size. So I spent a while climbing in and out with the rollcage in position, trying

to work out where the steering wheel should go.

However, there are a couple of problems with the roll cage. One is that is seems rather high, but that's probably not a huge problem. However, the other one is rather more serious in that the side tube of the cage (the one that goes to the side protection gubbins) would really like to be in the same place as my shoulder is. Curiously, the top side tube of the cage is bent so as to provide a bit more room and it would seem sensible to do the same to the side diagonal tube.

I suspect that this problem is serious enough to make some modifications necessary. (Not sure how easy it is to modify the roll cage really?) So, I'll phone Martin Bell on Monday and see what he suggests.

Well, I decided to follow Lady Macbeth's advice concerned with screwing my courage

to the sticking post, whateve one of those is and decided to try welding the removeable boss to the column. First

of all I cut the column down a bit and hacked it around to sort of nearly but not quite fit the end of the boss.

The next problem was that is clearly very important to make the boss in line with the column.

Well, I decided to follow Lady Macbeth's advice concerned with screwing my courage

to the sticking post, whateve one of those is and decided to try welding the removeable boss to the column. First

of all I cut the column down a bit and hacked it around to sort of nearly but not quite fit the end of the boss.

The next problem was that is clearly very important to make the boss in line with the column.

So, I constructed a model of the Eiffel tower out of one steering column, a removeable steering wheel boss and 18 tie-wraps. After a lot of jiggling about with a spirit level and fiddling with the tiewraps everything seemed to be about in line and I tack-welded the boss to the column. (Made a bit of a mess of the bench though.)

After that I welded it properly, worrying all the time that it would just fall apart half way round a circuit or be so out of alignment that it was unusable.

However, it seemed to work all right (ish) and this is the final result. (Unfortunately

blurred but it's the only photo I took.)

However, it seemed to work all right (ish) and this is the final result. (Unfortunately

blurred but it's the only photo I took.)

After that I put the column back into the car and adjusted it, with the aid

of some spacers on the mounting made out of the Honda engine mounts that I didn't use, to be in about the position

that initial tests had shown to be right. I have a feeling that it'll have to be a bit closer to me than it is

at the moment but it's no big deal to modify.

After that I put the column back into the car and adjusted it, with the aid

of some spacers on the mounting made out of the Honda engine mounts that I didn't use, to be in about the position

that initial tests had shown to be right. I have a feeling that it'll have to be a bit closer to me than it is

at the moment but it's no big deal to modify.

In this photo the wheel is protected with the polythene, as the suede covering is amazingly good at picking up bits (bit of aluminium are a favourite) and not letting go of them.

To finish off a rather short day I put some of the wiring back into position (I took it off for fitting the engine) and did the wiring for the low fluid warning from the brake fluid reservoir. There really ought to be a handbrake switch to as to be able to test the light but I think that's not going to happen.