Time to get on with the details of the engine. So, I first put a couple of bits

back together in that I fitted the speed sensor properly and then reattached some of the cooling pipework, including

the thermostat that I'd taken off to get at the engine properly.

Time to get on with the details of the engine. So, I first put a couple of bits

back together in that I fitted the speed sensor properly and then reattached some of the cooling pipework, including

the thermostat that I'd taken off to get at the engine properly.

Then, I started looking at getting the carburettors back on. They're attached by rubber clamps that I presume do the usual thing of keeping vibration away from the float chambers so as to stop the fuel getting all frothy.

Mind you, there's lots of bits of pipes and things that

are a bit confusing at the moment. First of all there seem to be vacuum outlets available from each cylinder. Two

of these were bunged up with little M5 bolts already and I bunged up the remaining two. Not sure what they could

have been for though. Do bikes have brake servos?

Mind you, there's lots of bits of pipes and things that

are a bit confusing at the moment. First of all there seem to be vacuum outlets available from each cylinder. Two

of these were bunged up with little M5 bolts already and I bunged up the remaining two. Not sure what they could

have been for though. Do bikes have brake servos?

The fuel pipe into the carbs is fairly obvious but this one is called the "vent pipe" in

the Haynes manual. The same tome says it goes into a pipe which is clipped somewhere but it doesn't say where it

is. I wonder...?

The fuel pipe into the carbs is fairly obvious but this one is called the "vent pipe" in

the Haynes manual. The same tome says it goes into a pipe which is clipped somewhere but it doesn't say where it

is. I wonder...?

This one (the one in the middle) is some sort of breather. The same Haynes manual describes

a small breather filter that it goes into. I guess I ought to have something similar, not sure how though.

This one (the one in the middle) is some sort of breather. The same Haynes manual describes

a small breather filter that it goes into. I guess I ought to have something similar, not sure how though.

After all that confusion I started looking at attaching a throttle cable. This is essentially a (push) bike brake cable that I got from Halfords. Not quite sure how to make this work yet though...watch this space.

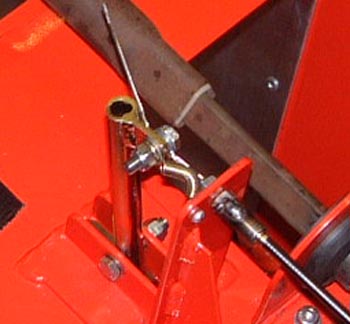

I made an adjuster for the bike cable out of a piece of M6 studding with a hole drilled

down the middle. (If anyone reading this is thinking of building a car, get a pillar drill. They're amazingly cheap

these days if you buy a cooking one and incredibly useful for doing things like this.) The bike cable then threads

through here and, with the end fitting filed suitably, fits snugly into the throttle cam on the bike carbs.

I made an adjuster for the bike cable out of a piece of M6 studding with a hole drilled

down the middle. (If anyone reading this is thinking of building a car, get a pillar drill. They're amazingly cheap

these days if you buy a cooking one and incredibly useful for doing things like this.) The bike cable then threads

through here and, with the end fitting filed suitably, fits snugly into the throttle cam on the bike carbs.

I'll need to do something similar at the other end of the cable.

With that I attached the carbs back to the engine. It was bit of a fiddle working

out how to position the clamps on the mounting rubbers so as to not bash into some other bit of the engine but

finally it fitted neatly.

With that I attached the carbs back to the engine. It was bit of a fiddle working

out how to position the clamps on the mounting rubbers so as to not bash into some other bit of the engine but

finally it fitted neatly.

With that I just finished the day's short build by pinning down some of the wiring at the front of the car.

I'm a couple of days late with this, but still. (Been doing lots of decorating

in the house.)

I'm a couple of days late with this, but still. (Been doing lots of decorating

in the house.)

Anyway, I moved onto the next bit of fitting the engine by fitting the throttle cable. First of all I tarted up the adjuster thing described above by welding a short piece of steel tube to the outer net, meaning that it holds the end of the cable in place. Next, I made a device up for the other end to clamp the cable to the end of the throttle pedal. This is essentially an M6 bolt with a 2mm hole drilled through the shank that the cable inner fits into. I mounted this all with an additional spring so that there are essentially two springs trying to close the throttle; this one and the one on the carb butterflies.

However, the throttle pedal travel isn't too impressive at the end of this, it might be a bit super-sensitive. I'll have to wait and see and try it.

Next, I started installing the fuel feed pipe. Having changed my mind a couple of times

I was intending to do this with some 3/8" fuel hose that I had left over from the Dax build. However, having

used that because it's the right size for the carb fitting it's obvious that it's really too large for the tails

on the fuel pump. (I had previously thought that 3/8" seemed a bit butch.)

Next, I started installing the fuel feed pipe. Having changed my mind a couple of times

I was intending to do this with some 3/8" fuel hose that I had left over from the Dax build. However, having

used that because it's the right size for the carb fitting it's obvious that it's really too large for the tails

on the fuel pump. (I had previously thought that 3/8" seemed a bit butch.)

So, perhaps I'll get some 5/16" fuel hose instead? Still not sure though.

One reason for the vacillation about the fuel line is that I'm a bit wary about the fuel tank. I bought this tank because: it was cheapish, is foam-filled and I had previously seen one at the KitCar Workshop for installation in a race Fury. However, the last time I was there I noticed that the car in question now had one of the (rather nasty in my opinion) plastic tanks that Fisher sell for the Fury fitted. Apparently, they'd had to modify the bodywork to fit the aluminium tank and the owner of the car wasn't too happy with it.

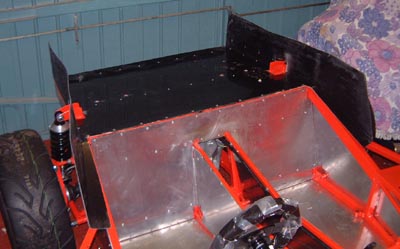

The problem is that in it's natural (and perhaps only) position the tank sits slightly

beyond the rear boot frame of the chassis, as shown here. The tank here is attached, in true race car fashion,

with a bunch of tie-wraps. I was looking at some photos of the new Formula BMWs the other day and significant parts

of the suspension systems, for example the damper gas accumulator cylinders, were attached in such a way.

The problem is that in it's natural (and perhaps only) position the tank sits slightly

beyond the rear boot frame of the chassis, as shown here. The tank here is attached, in true race car fashion,

with a bunch of tie-wraps. I was looking at some photos of the new Formula BMWs the other day and significant parts

of the suspension systems, for example the damper gas accumulator cylinders, were attached in such a way.

The modification that I saw to the bodywork essentially has a small cutaway at the bottom rear of the rear tub, presumably to clear the bottom rear bit of the tank.

However, to know what will happen I really need the bodywork. So, I phoned Martin up the other day and was checking to see when it would arrive. The answer is this coming Friday so I booked a van today to drive over to Northampton on Friday and pick it up. (I have to go to the USA on Saturday.) I was also asking Martin about the problem with the track rod ends as mentioned earlier. He's still trying to find a decent source of TREs that don't conflict with the disc but pointed out to me that just using a tie-wrap round the boot would hold it in place for now. Don't know why I didn't think of that, as it's obvious.

Finally, several people have pointed out that the vacuum take-offs, as discussed elsewhere, are there to allow for carb balancing. Obvious really, and thanks to everyone who took the time to write and tell me.

I picked up a van early from Cambridge and drove over to Rushden, again, to

get the bodywork. While there Martin also gave me some new hub nuts and a couple of different track rod ends. At

first sight they look as though they'll fit fine, but I've yet to see.

I picked up a van early from Cambridge and drove over to Rushden, again, to

get the bodywork. While there Martin also gave me some new hub nuts and a couple of different track rod ends. At

first sight they look as though they'll fit fine, but I've yet to see.

The bodywork is, errrm, very red. In fact, it seems to match the red powder coating pretty well. This is almost a shame as I'm bound to mess up the powder coating modifying the cage.

At the moment, the GRP looks pretty high quality. I ordered the lightweight version but

paid a bit more to get the version that used woven rovings rather than chopped glass fibre strands. This seems

to have two benefits. Firstly, it's a bit stronger which is useful on thin bodywork. Also, it doesn't have lots

of bits sticking out that make GRP such a pain to work with.

At the moment, the GRP looks pretty high quality. I ordered the lightweight version but

paid a bit more to get the version that used woven rovings rather than chopped glass fibre strands. This seems

to have two benefits. Firstly, it's a bit stronger which is useful on thin bodywork. Also, it doesn't have lots

of bits sticking out that make GRP such a pain to work with.

However, the big problem I have now is that working around the Dax is going to be really difficult, as the bodywork makes the car much bigger. I really have to get on and get it sold. I'm off to the US on business for a few days. When I get back I'll see about taxing it and then advertising it. It should be about the right time of year to do it.

Having got back from the US (and a very pleasant skiing trip to New England)

I managed to brave the jet lag and the cold and get into the garage again. While I was away I got a spacer for

the sprocket adapter, which I mentioned a while ago

was required. This was fitted easily and the sprocket torqued up to an alarmingly low figure, as is the case for

everything on the engine.

Having got back from the US (and a very pleasant skiing trip to New England)

I managed to brave the jet lag and the cold and get into the garage again. While I was away I got a spacer for

the sprocket adapter, which I mentioned a while ago

was required. This was fitted easily and the sprocket torqued up to an alarmingly low figure, as is the case for

everything on the engine.

Then I fitted the hinge frame to the front of the chassis. I want to fit the radiator next and it seems as though the hinge frame will protect the radiator from being bashed into by my clumsy size 12s.

Then I moved on to fitting the radiator. This is a wonderful piece of plastic and aluminium engineering and seems to be a slightly larger version of the one fitted to the Westfield many moons ago. It has some blank plastic bushes on it and after a musing session I decided to tap these to M6x1 and then bolt into them through the mountings on the chassis. However, there wasn't time to finish this straight away, maybe tomorrow...

I had to go away for most of the weekend. However, I did manage to a do a couple of small things. First

of all the radiator was attached. This was made slightly tricky by the fan switch fouling the mounting brackets

but I used some small spacers to move the radiator forward by a few millimetres to fix this. Hopefully it won't

foul the bonnet!

I had to go away for most of the weekend. However, I did manage to a do a couple of small things. First

of all the radiator was attached. This was made slightly tricky by the fan switch fouling the mounting brackets

but I used some small spacers to move the radiator forward by a few millimetres to fix this. Hopefully it won't

foul the bonnet!

With this in place I can work out what cooling pipework I need, and how to arrange for an expansion tank.

Next thing seems to be to start looking at the bodywork. Unfortunately, as the

Dax is still living in the garage (covered by the gruesome old curtains you can see in some of the photos) it's

rather hard to get at the car and I think I'll have to stick it back on the stands to get a little more space.

Next thing seems to be to start looking at the bodywork. Unfortunately, as the

Dax is still living in the garage (covered by the gruesome old curtains you can see in some of the photos) it's

rather hard to get at the car and I think I'll have to stick it back on the stands to get a little more space.

According to the "manual" the first thing to do is to fit the boot floor which is a sort of flat moulding that goes on the rear of the chassis and might do something to support the rear bodywork, although it's hard to see what at the moment. Fitting this is a little more tricky than in the normal car as the raised suspension mounts on the raised chassis conflict slightly with the panel but it's easily relieved with a Dremel. With the panel rivetted in place it looks like this photo here. (Mind you, I keep wondering if I should have rivnutted it into position...)

Finally, I ordered the transponder that I'll need for the race series the other day. With luck it should arrive early next week.