Hmm, auspicious date is that... Anyway, I got on with doing some of the little

fettling jobs today. With just about a month before the next race, although I'll try and get some testing at Snetterton

in too, I've got the chance to do some of these things.

Hmm, auspicious date is that... Anyway, I got on with doing some of the little

fettling jobs today. With just about a month before the next race, although I'll try and get some testing at Snetterton

in too, I've got the chance to do some of these things.

First thing was to change the cam chain tensioner. I'd bought a brand new one off Mr Honda and it's here on the right. Although I had had to take it to bits at Oulton the old one seems fine really so I'll just put it in the tool box and keep it for spares. It's interesting how little worn the bit that presses on the chain is, the new one is practially indistinguishable from the original one.

One other thing I bought from Honda was a new support for the outer of the clutch cable. For some reason I'd got a bit jumpy about the one I made. So, I fitted the new one but, realistically, it probably won't make a scrap of difference.

One problem I had at Oulton was that my heels kept sticking to the floor just

behind the pedals. So, I had a look around and it seems as though some of the crop of rubber that always ends up

in the car had got there and, probably because it's a bit hot down there, had got lodged under my feet and gone

all sticky and unpleasant.

One problem I had at Oulton was that my heels kept sticking to the floor just

behind the pedals. So, I had a look around and it seems as though some of the crop of rubber that always ends up

in the car had got there and, probably because it's a bit hot down there, had got lodged under my feet and gone

all sticky and unpleasant.

So, I spent a while cleaning it off with the aid of a rather nasty solvent. Once I get a tonneau sorted it might reduce the amount of rubber slightly which would be a relief.

The scrutineers at Oulton had requested that improve the way the tub sealed to the scuttle

(cut off, of course, to make the tub removeable). So, I took off the rather Heath Robinson arrangment of Dzus fasteners

and little aluminium brackets that was there before and fashioned this "ledge" of aluminium that is rivetted

to the scuttle.

The scrutineers at Oulton had requested that improve the way the tub sealed to the scuttle

(cut off, of course, to make the tub removeable). So, I took off the rather Heath Robinson arrangment of Dzus fasteners

and little aluminium brackets that was there before and fashioned this "ledge" of aluminium that is rivetted

to the scuttle.

I actually stuck some foam onto it after this photo was taken and in this form it seems to provide pretty good support. I was originally intending to put some fasteners in so that the tub could be secured down but I actually chose to leave it like this and just rely on the bonner pressing down on the lip on the front of the tub, which it does pretty firmly.

This is in fact aided by the fact that I also repositioned the bonnet slightly.

Ever since I fitted the yellow bonnet in rather a rush I've wanted to move the left hand side of it backwards slightly,

which entails modifying the fitting of the bonnet to the hinges on the frame.

This is in fact aided by the fact that I also repositioned the bonnet slightly.

Ever since I fitted the yellow bonnet in rather a rush I've wanted to move the left hand side of it backwards slightly,

which entails modifying the fitting of the bonnet to the hinges on the frame.

This time, I've got around to it. I moved the left had side back by about 10mm and it looks loads better, mainly because the gap between bonnet and scuttle is now the same on both sides of the car.

I also changed the bonnet catches from the ones that I fitted in a rush to some rather firmer ones.

All this has left all the bodywork fitting more securely again. In fact, it's rather more like it used to be; it seems to have slackened off as I've driven the car.

So, as soon as I got the bonnet fitting better, I took it off again. After thinking a lot

about the engine I have decided to fit the oil cooler I've had for some time. Although the highest temperature

I've seen is about 115°, something the oil is well capable of withstanding, a lot of people have commented

that the engines lose power when the temperatures get too high. I doubt, to be honest, that there can be much effect

as the water temperatures have always been fine but I might as well do it as I'm certain it will be necessary if

I get around to flat-bottoming the car.

So, as soon as I got the bonnet fitting better, I took it off again. After thinking a lot

about the engine I have decided to fit the oil cooler I've had for some time. Although the highest temperature

I've seen is about 115°, something the oil is well capable of withstanding, a lot of people have commented

that the engines lose power when the temperatures get too high. I doubt, to be honest, that there can be much effect

as the water temperatures have always been fine but I might as well do it as I'm certain it will be necessary if

I get around to flat-bottoming the car.

So, I took the bonnet off and mounted the cooler directly in front of the water radiator. There's about a 10mm gap which I can easily seal up with some ducting if it happens that I lose too much water cooling. The cooler connects into the oil system with a sandwich plate that fits under the oil filter. Curiously, the sandwich plate came with an adapter that I didn't seem to need. I hope this is because the various 'blade engines are different and I've got the sort that doesn't need this adapter. It seems that it would allow the oil/water intercooler to be mounted with a thinner nut which would allow the sandwich plate to bolt in more snugly. Mine doesn't seem to need it though.

The whole lot is piped together with some rather snazzy stainless braided oil hoses. I'm hoping that the position I've put this lot in will be find once the bonnet is back on, but I have this horrible feeling that I'll discover something untoward.

The next thing to do will be to change the oil, again, and spin the engine around until I get some oil pressure. As there's a lot of filter/cooler to fill up that could take some time...

I phoned Snetterton today and booked myself into the test session that's taking place there on the 24th. After that I might well book something for a fortnight after that, which is the day before the next race. However, we'll see how it goes.

Having piped up the oil cooler yesterday, I refilled with oil today and got the engine running again. However, there's now rather a lot of oil pressure unions and I'd like to run the engine for a while to check that nothing untoward is going to happen. That will probably have to wait for the weekend though. The other thing that's needed with respect to this lot is to replace the grill in the nose opening; I had to remove it to get decent access to the bolts that attach the bonnet to the hinges.

I moved on to the usual post-race cleaning up and took the pads out of the front brakes.

They're getting in a worse and worse state, and are now quite worn, as you can see on the photo. I need to get

some more pads to keep in the toolbox at least...

I moved on to the usual post-race cleaning up and took the pads out of the front brakes.

They're getting in a worse and worse state, and are now quite worn, as you can see on the photo. I need to get

some more pads to keep in the toolbox at least...

These pads are EBC greenstuff and I might try some different ones, just to see if there's any significant difference.

I ordered some new pads today to replace the rather sorry looking ones above. This time

I ordered some Mintex ones, in fact in two different compounds (1144 and 1155), so as to try them both. I guess

I ought to get some new shoes for the rear too though. The rear ones are less important though and I suppose I

could just get standard replacement motor factor ones.

I ordered some new pads today to replace the rather sorry looking ones above. This time

I ordered some Mintex ones, in fact in two different compounds (1144 and 1155), so as to try them both. I guess

I ought to get some new shoes for the rear too though. The rear ones are less important though and I suppose I

could just get standard replacement motor factor ones.

I've got a problem with the exhaust in that the tail pipe I made up is attached to the exhaust body using some self tappers and they keep working loose. Hence, I'm going to weld the tail pipe to the body of the can. That should sort it. However, while the sidepod was off (I can't do the welding yet as I need to reclaim my welder from Craig's garage where it's gone on extended holiday) I was wondering about replacing the exhaust now with a straight-through one that might release a couple of currently asphyxiated horses. Hmmm, there might just be time before the Snetterton test next week. Watch this space!

Apart from that I spent a while cleaning up wheels and brakes and getting the car all sorted. One thing I think I do need to do for the next test is to properly record every lap time. I perhaps need to get a different form sorted!

I've found a bit of time at the weekend to get on top of getting the car back

together for the Snetterton test. At the moment I'm getting worried that it's going to be wet which will be just

horrible.

I've found a bit of time at the weekend to get on top of getting the car back

together for the Snetterton test. At the moment I'm getting worried that it's going to be wet which will be just

horrible.

I got the Mintex 1144 pads which I fitted easily. The nice thing about the Hispec brakes is that it's dead easy to get the pads in and out. Being racing calipers there's no faffing about with anti-rattle springs and the like. The new calipers have got some very thing, slightly bungy, backing on them. Not sure what difference it will make.

It came to my attention that I had, sitting in my garage, Craig's straight through exhaust for his Phoenix. You can see this can above my Fireblade one here. (Craig's is the shiny one!) After checking with him that it was ok to use it and buy him another one I eventually decided to have a go with it. I had to chop off the existing exhaust mounting from where it was welded at the end of manifold pipework. Unfortunately, The straight-through silencer is about 600g heavier than the original 'blade one which is a shame.

After taking the mounting flange off and having a look at it, it became obvious that it

was a good job I'd decided to change the can because the mounting flange was seriously cracked and wouldn't have

lasted that much longer. The photo shows just one of the cracks and eventually they would have gone all around

the flange and joined up, and fallen off!

After taking the mounting flange off and having a look at it, it became obvious that it

was a good job I'd decided to change the can because the mounting flange was seriously cracked and wouldn't have

lasted that much longer. The photo shows just one of the cracks and eventually they would have gone all around

the flange and joined up, and fallen off!

I had heard, from Dan who had done something similar, that this was a problem and I'd been looking for it, although obviously not carefully enough. These flanges are actually intended to be the ends of a home-made silencer can and are obviously not up to the vibration of a complete can hanging on them.

So, with that but chopped off I fitted Craig's silencer. There was the inevitable

problem getting it to clear the side impact protection gubbins but after a while it was made to fit fine. It's

hard-mounted at the moment, mainly as a bit of an experiment to see how it goes. You can just see the bracket at

the end of the exhaust.

So, with that but chopped off I fitted Craig's silencer. There was the inevitable

problem getting it to clear the side impact protection gubbins but after a while it was made to fit fine. It's

hard-mounted at the moment, mainly as a bit of an experiment to see how it goes. You can just see the bracket at

the end of the exhaust.

While I was here, I was wondering why one earth I needed the side impact stuff on this side of the car. I don't intend ever racing with a passenger and all that metal work isn't light. Perhaps I might remove it at some point to save a bit of weight.

On the same topic, I was wondering about removing the radiator fan. At the moment it's probably doing nothing other than clogging up the air flow through the radiator as it never comes on during a race. The only problem would be that I'd have to be a lot more careful about what happens in the assembly area and on the run up to the grid. I'll think about that and see. Again, it would save a bit of weight.

So, after that I put the sidepod back on and moved

on to other things. One other thing I wanted to do was to try moving up the rear engine mounting slightly so as

to get the engine more closely horizontal, and to match the modification

that I did to the front engine mounts a while ago.

So, after that I put the sidepod back on and moved

on to other things. One other thing I wanted to do was to try moving up the rear engine mounting slightly so as

to get the engine more closely horizontal, and to match the modification

that I did to the front engine mounts a while ago.

At the time I hadn't had the time to make up a similar spacer for the rear mounting but I saw something that Chris Seaman had done on his car at Silverstone, which was just to invert the normal Fisher mounting which has a very similar effect. So, I slackened off the mountings and lifted the whole engine up slightly, enough to take out the rear mounting and turn it over.

It ended up about 10mm higher which is great, as I could then drop down the suspension a bit more. In fact, the front of the car is just about right but the rear was still too high, so that the engine wasn't lower than the 75mm minimum height. With the engine moved like this I could lower the rear spring platforms so that it was closer to where I wanted it to be. I shall have to see at Snetterton when I suffer again from the tyres rubbing on the bodywork. This time, though, I will fix this by just grinding off more of the bodywork, as I did a while ago.

With that I put all the bodywork back on and ran the car for a while to check that the oil cooler got warm, it did, and that nothing leaked out of the oil pipework that I've added, it didn't. I did get a bit concerned though, by a small patch of something wet that appeared beneath the car. It seemed to be water but I couldn't see where it could have come out of the cooling system, it might just be because I pushed the car out onto the drive and promptly pushed it back when it rained. Not sure about that though, as I might have been able to smell some antifreeze in the water. Hmmm...

The only thing left to do before the test at Snetterton is to refit the grill over the front aperture in the bonnet. Unfortunately, I don't have enough mesh right now so I'm going to have to do to MacKay's tomorrow to get somet more.

Well, it's Sunday evening now but we had a pretty successful day testing at

Snetterton on Friday. Tom and I got up early (why does motor racing go hand in hand with early starts?) and drove

around the corner to pick up DH2 who had kindly offered to

help out during the day. We then drove to Snetterton, which is only about an hour away from home, even with a trailer.

Well, it's Sunday evening now but we had a pretty successful day testing at

Snetterton on Friday. Tom and I got up early (why does motor racing go hand in hand with early starts?) and drove

around the corner to pick up DH2 who had kindly offered to

help out during the day. We then drove to Snetterton, which is only about an hour away from home, even with a trailer.

In fact, there were quite a bunch of us there. Adrian was there with his Genesis and Matt in his Megagrad Caterham. Matt's a vastly more experienced racer than either Adrian or I and I was expecting to be miles slower than him, although supposedly even a class C RGB racer has the capability of being quicker than his car. Certainly when we were at Cadwell Park a while ago he was miles quicker than me. Guy, another local Caterham driver and very succesful racer and sprinter, was there too. I was looking forward to what he had to say, as he's pretty analytical about race driving. What's more, unlike me, he took some photos such as the one just about.

The day went pretty well. Once I'd learnt the circuit, this was my first time at Snetterton, I got to about 1:28 and by the end of the day I was down to 1:22.5s, or thereabouts. Unfortunately, that would have put me in the middle of the grid at the race here in April, something like 8th in class. What's more, I set that time in the last session of the day and qualifying only lasts 15 minutes, not three hours...

Still, there was lots of things to think about. One interesting thing is that I seemed to be plagued rather less by the awful transmission clonking. (Having thought at Cadwell that it was better than it used to be I now think I was fooling myself.) Assuming I'm not in self-delusion mode again the only thing I can think of that might have changed it is the shift in position of the engine as mentioned above. Whatever, if it is feeling better it will be a great relief.

My driving is still, not to put too fine a point on it, crap. In particular

I seem to have two bad habits: turning in too early and too quick. Taken together these things limit my exit speed

from a corner seriously. All the same, Snetterton has a very long back straight and I was still getting to about

10,200 rpm in top which must be seriously quick. I think I'm glad that my speedo isn't calibrated properly.

My driving is still, not to put too fine a point on it, crap. In particular

I seem to have two bad habits: turning in too early and too quick. Taken together these things limit my exit speed

from a corner seriously. All the same, Snetterton has a very long back straight and I was still getting to about

10,200 rpm in top which must be seriously quick. I think I'm glad that my speedo isn't calibrated properly.

Good times at Snetterton are predicated on being able to use the kerbs properly and I found it really difficult to run the car over the kerbs at, in particular, the Russell chicane. On reflecting on it later on, I suspect that at least some of this difficulty is not ensuring that, first, the wheel on the kerb is actually unloaded. As it was running over the kerbs so often made my car just leap sideways. Perhaps if I changed the lines a bit...? But, thinking that way indicates that I'm in control of the lines which is, I suspect, a dangerous assumption.

One worry is that gear selection seems to be getting progressively more difficult, especially into 5th and 6th. I'm actually in half a mind to take the engine out and have a look at the gearbox before the next race.

All in all though, it was a great day, made better by having such a crowd of people there at the same time. On the way home we stopped in a pub and allowed ourselves a celebratory drink while we listened to Adrian regaling us with stories of his day. (He was somewhat wired by then..:-) I rather like the photo that Guy took of the three cars and trailers in the car park, as seen above.

Back in the garage, it was time to get back to the car. I seem to be suffering from too much understeer,

although this could well be just a consequence of the errors mentioned above. On getting back into the garage today

I had a good look at the tyres and this photo here is of the left front which is the most loaded tyre at Snetterton

(probably in general too). Obviously, the tyre's rather worn but it's becoming apparent that the outer side of

the tyre is rather worse. In fact, you can see a pronounced chamfer on the left of the tyre which wasn't there

before Snetterton.

Back in the garage, it was time to get back to the car. I seem to be suffering from too much understeer,

although this could well be just a consequence of the errors mentioned above. On getting back into the garage today

I had a good look at the tyres and this photo here is of the left front which is the most loaded tyre at Snetterton

(probably in general too). Obviously, the tyre's rather worn but it's becoming apparent that the outer side of

the tyre is rather worse. In fact, you can see a pronounced chamfer on the left of the tyre which wasn't there

before Snetterton.

So, I need to do somthing about this and I need to get at least some new tyres before the next outing. Not sure what yet though.

One thing I did do, though, was to increase the amount of camber at the front. It seems as though not all of the tyre is actually being used and increasing the camber might well address that.

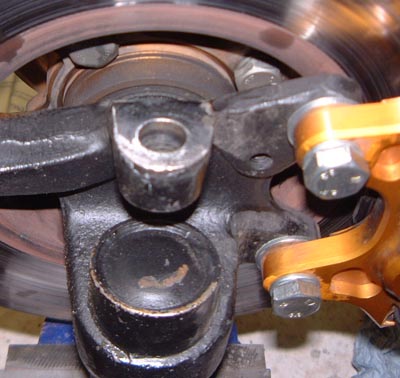

One problem I had adjusting the camber, which I've had before was actually getting a ball

joint breaker into the suspension so as to remove the lower ball joint. This is the same joint that has caused

problems in the past by both destroying the rubber boot on the ball joint and binding up so that the suspension

couldn't droop sufficiently. I had seen something on Craig's

site that reflects the same situation and he had been told by the people at Stuart Taylor to grind away a bit of the upright so as to prevent this happening.

One problem I had adjusting the camber, which I've had before was actually getting a ball

joint breaker into the suspension so as to remove the lower ball joint. This is the same joint that has caused

problems in the past by both destroying the rubber boot on the ball joint and binding up so that the suspension

couldn't droop sufficiently. I had seen something on Craig's

site that reflects the same situation and he had been told by the people at Stuart Taylor to grind away a bit of the upright so as to prevent this happening.

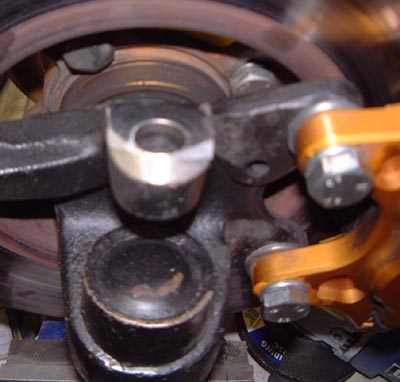

On reflecting on it, this seems a pretty good idea and I did so, the two photos here are the before and after ones. Unfortunately, the camera insisted on blurring the after one and I'm not going to take the car apart again so that you get a better photo to look at!

With that amount of grinding the suspension certainly does move better, although I suspect

at the normal setting it won't make any difference on the track. It does, though, make it dramatically easier to

get the ball joint breaker in and out.

With that amount of grinding the suspension certainly does move better, although I suspect

at the normal setting it won't make any difference on the track. It does, though, make it dramatically easier to

get the ball joint breaker in and out.

With the camber readjusted I adjusted the tracking. This was not toeing-in too much, presumably because the various camber and ridehieght changes have affected it. One thing that I'd like to do over the winter is spend a while carefully measuring the car to see if there's any bump steer. I'll need to make a gauge like the one that's described in the Allan Staniforth book to do this, but it should increase my confidence in the suspension being set up properly.

One other interesting consequence of Snetterton is that the high wind speeds on the Revett straight bent the mounting of the central mirror! This is a bit of 2mm aluminium that is tie-wrapped around the roll cage. (This is a surprisingly tough mounting mechanism.) So, I repositioned the mirror slightly, trying to make the lever length a bit shorter so that the forces won't have quite the same effect. Difficult to test though, before going on the track again.