After the Brands race i had a few days off and haven't really got back to writing

this diary. However, here we are again.

After the Brands race i had a few days off and haven't really got back to writing

this diary. However, here we are again.

The first things that's happened is that I checked the car over fairly carefully after the race. One thing of interest was the tyres which almost seem to have more rubber on them now then when I started the race. I can only assume that one of the previous races (perhaps the Formula 4 one?) left loads of rubber on the track which was then picked up by us.

The same rubber was inside the car too, in fact it was everywhere really. Inside the car there were just piles of it around the place. All very odd. It'll be interesting to see, the next time out, how this varies, if at all.

You can see on this picture here the rubber on the tyre, as well as all the gravel that's still sticking to the tyre. I don't really have a feel yet for how worn the tyres are. I guess I ought to measure the tread depth before and after the next race to at least get an idea how much rubber is disappearing.

With regard to the race, the official (albeit preliminary at the moment) results are now available on the 750MC web site. This is a direct link to the Acrobat file. I'm actually feeling better about the results now, I'll just have to try a bit harder next time, although hopefully without stuffing it into the barriers. Mind you, if it's wet I'll be very, very, very, very, careful.

One major thing I wanted to look at was the ride height of the car which just seems too high, mainly so that the sump clears the ground by the required clearance.

In order to get this to work rather better, I've lifted

the engine slightly, by putting a 1/2" thick chunk of aluminium under the two front engine mountings. I found

that I didn't need to lift the rear engine mounting, as actually the engine always tipped down slightly and it's

now more or less horizontal.

In order to get this to work rather better, I've lifted

the engine slightly, by putting a 1/2" thick chunk of aluminium under the two front engine mountings. I found

that I didn't need to lift the rear engine mounting, as actually the engine always tipped down slightly and it's

now more or less horizontal.

With the engine like this the whole chassis could be dropped down a bit and although it's still a bit more than 3", the minimum clearance, it's a good deal closer. One of the reasons why it's still a bit high is that I really need to get some shorter springs. I suppose I could persuade Martin to swap the current ones but they might come in useful at some point so I'll get some new ones. For now, at least, I'll stick to the same spring rates (275 lb/in at the front and 225 lb/in at the rear) as I really have no clue how I would change them.

With the ride height done I carefully checked the front camber settings and got them back to where they ought to be. I'm a bit concerned that the adjustment on each side is rather different. Either the chassis is not exactly straight (I've always been slightly concerned about that) or, more likely, the garage floor just isn't flat enough. I've actually borrowed a set of corner weight scales so that should give me a chance to get the car as, effectively, flat as possible.

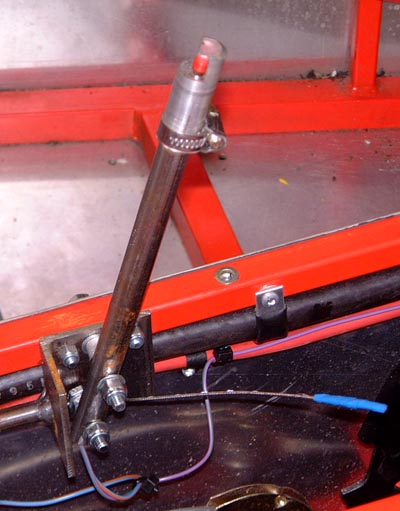

It's good to be getting to new things, really. One of these is a gear indicator.

I got one from Martin a while ago that I've been trying to find the time to fit. It works by comparing road speed

and engine speed and you can teach it what the gear ratios, essentially by just driving along in the gear in question.

I'm hoping I can do that on stands in the garage but we'll see.

It's good to be getting to new things, really. One of these is a gear indicator.

I got one from Martin a while ago that I've been trying to find the time to fit. It works by comparing road speed

and engine speed and you can teach it what the gear ratios, essentially by just driving along in the gear in question.

I'm hoping I can do that on stands in the garage but we'll see.

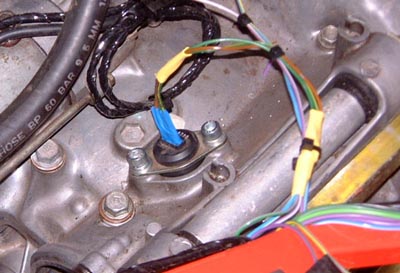

The first step though, is to get a speed sender working. I got hold, a while ago, of a Blackbird speed sender which looks pretty much like the 'blade one and nicely plugs up the hole in the gearbox. After some hunting around I managed to find out how the sender was wired. I don't actually have a connector for the sender, the blade one doesn't fit, but I managed to make a connector of sorts out of some other parts of the old 'blade loom. With all this wired up I checked, with an oscilloscope, that there was actually some output from the sender. There's been a lot of discussion lately about this and the need, or otherwise, for a pull-up resistor from the sender output. I used such a resistor and managed to get a nice clean signal from the sender. As soon as I've got a moment I will fit the gear indicator itself and see if I can get it to work.

I've wanted for a while to get the car on a rolling

road to see if the engine was at least working moderately well. So, yesterday I took it over to TTS in Northampton.

Not very much to report really, especially as their insurance precluded me being in the workshop as they were running

the car. It sounded fabulous though! The end result was to use some leaner main jets which made things work rather

better. The chap at TTS was of the opinion that using a race can would liberate a few more bhp, and would probably

need to richer jets reinstating.

I've wanted for a while to get the car on a rolling

road to see if the engine was at least working moderately well. So, yesterday I took it over to TTS in Northampton.

Not very much to report really, especially as their insurance precluded me being in the workshop as they were running

the car. It sounded fabulous though! The end result was to use some leaner main jets which made things work rather

better. The chap at TTS was of the opinion that using a race can would liberate a few more bhp, and would probably

need to richer jets reinstating.

All the same, it looks as though it was worthwhile, albeit not cheap at all. You can see the curves rather more clearly in the full acrobat document. Note that the second curve is for a run through the gears, which is quite illuminating.

The figures, by the way, are for power at the wheels not at the non-existent flywheel. Someone recently said that some class C cars were making 128bhp at the wheels which seems pretty exorbitant....

Later on...and back in the garage. I finished fitting the gear

indicator. You have to train this by poking a little plastic key into the back and telling it how many gears you've

got and then driving along in those gears until it thinks it knows what the ratios are. I did this by driving along

with the rear wheels off the ground. I'm not sure whether the little blighter has learnt properly but we'll see

when the car is next out.

Later on...and back in the garage. I finished fitting the gear

indicator. You have to train this by poking a little plastic key into the back and telling it how many gears you've

got and then driving along in those gears until it thinks it knows what the ratios are. I did this by driving along

with the rear wheels off the ground. I'm not sure whether the little blighter has learnt properly but we'll see

when the car is next out.

However, while I was doing this the transmission clonking (as mentioned on the to-do page was horribly obvious. Of course, like this there's no load on the drive train and this seems to exacerbate things which I'm coming to the conclusion is down to backlash in the diff. The end result is, to say the least, horrible and I'm intending to have a look at a friend's car that also has a Freelander diff to see if that has the same amount of backlash as mine.

The next instrument to look at fitting will be the little (push) bike speedo that I've bought. With that installed the dash is going to look rather full, and cluttered!

I've been looking at how to fit the bike speedo. As part of that I was testing

what it would read up to. The speed sensor is a reed switch/magnet combination (like the one I had such trouble

with on the Dax). However, at first sight this seems to work fine. I tested it by taping the magnet to the drum

of a large hole saw in an electric drill and holding the reed switch sensor vaguely near the whirring magnet. As

you can see, this bike got up to 115mph, as fast as the drill could go, although the rider's clearly now exhausted

as he's stopped completely.

I've been looking at how to fit the bike speedo. As part of that I was testing

what it would read up to. The speed sensor is a reed switch/magnet combination (like the one I had such trouble

with on the Dax). However, at first sight this seems to work fine. I tested it by taping the magnet to the drum

of a large hole saw in an electric drill and holding the reed switch sensor vaguely near the whirring magnet. As

you can see, this bike got up to 115mph, as fast as the drill could go, although the rider's clearly now exhausted

as he's stopped completely.

I've ordered some neodymium magnets that I can epoxy to a wheel rim. Hopefully they'll work for tripping the reed switch too. Obviously, I'll also need to make some sort of bracket to hold the reed switch nearish to a wheel rim. I'm not sure yet whether to make it a front wheel or a rear one. The rear ones have the obvious advantage of not steering which makes them a bit more stable.

I had another look at the transmission backlash this evening, especially after looking at Craig's diff which seems to have almost no discernable play in the pinion on the front of the diff. Mine is rather more than that in that there's about 13mm of free movement at the tyre surface that's down to the backlash in the diff. That amount works out to 0.8° of free play on the diff input. However, there's about 45mm of free movement when taking into account the gearbox itself, which is about 3° of free play. Hence, perhaps this is just down to the gearbox itself. Still seems a rather large amount of free play though. I'm definitely going to try and talk to Martin at the Kit Car Workshop about this.

I don't seem to have made much progress this weekend, although I spent quite

a lot of time in the garage. The main thing, though, was to sort out the speedo. I attached the sensor, which is

meant to go on the front forks of a bike really, to a small aluminium bracket attached to the top of the rear upright.

Needless to say, I had to extend the wiring from that expected to used on the bike, but as the sensor is only a

reed switch that's no big deal.

I don't seem to have made much progress this weekend, although I spent quite

a lot of time in the garage. The main thing, though, was to sort out the speedo. I attached the sensor, which is

meant to go on the front forks of a bike really, to a small aluminium bracket attached to the top of the rear upright.

Needless to say, I had to extend the wiring from that expected to used on the bike, but as the sensor is only a

reed switch that's no big deal.

I glued a small neodymium magnet to the inside of the wheel and adjusted the sensor to be close(ish) to the magnet. At first sight it does seem to work fine, although only time will tell really. For some reason this sensor does seem to work remarkably better than the one I tried to use on the Dax. However, that one came from Greengauges...

I attached the speedo itself to the dash in such a position that I came (just) see it through the steering

wheel. It's sprt of half-obscuring the neutral light but that's no big deal as the gear indicator does that function

as well. The mountings for the speedo are, of course, supposed to be work when attached to the handlebars on a

bike. So, they needed some fiddling to work here, mainly with the addition of a couple of tie-wraps.

I attached the speedo itself to the dash in such a position that I came (just) see it through the steering

wheel. It's sprt of half-obscuring the neutral light but that's no big deal as the gear indicator does that function

as well. The mountings for the speedo are, of course, supposed to be work when attached to the handlebars on a

bike. So, they needed some fiddling to work here, mainly with the addition of a couple of tie-wraps.

One of the reasons for getting this particular model of bike speedo is that it incorporates a "ride time" timer (which is what the lower row of zeroes is in the photo). As the RGB races are a specific time then this is useful for knowing how far through the race one is.

While I was looking at this it occurred to me that perhaps it was a good thing that I hadn't bought a DigiDash as I don't think it would fitted. I have to have the steering wheel, and therefore column, higher up than most and I'm not sure if the amount of space left is sufficient to get a DigiDash in.

One other thing in the garage was that I spent a while siphoning all the fuel out of the tank and then pouring it back in slowly and, along the way, calibrating a stick that I can poke into the tank so that I can know how much fuel is actually in there. Unfortunately, it seems as though the bottom 2 litres or so cannot be sucked up by the outlet. However, that shouldn't cause a problem as I can't see me doing any endurance races just yet.

I've spent quite a time looking into the drivetain clonking. It may well be that the only conclusion is that "They All Do That Sir" but I'll keep looking. I spoke to Martin about the play in the gearbox and it is apparently normal. He said that the next time I was up there he would show me why it's the case. Of course, this doesn't explain why the clonking is there. I'll try and find time to go and have a look at Dave's diff this week to see if his clonks like mine does. A further possibility is that there is a Fisher "set up and handling" day this coming Sunday at which I could talk to both Martin and Mark Fisher about the problem.

I sent in an entry for the race at Lydden Hill in a couple of weeks. I still need to get some more track time in before that, but have not come up with a decent way of doing that. Perhaps I'll have to submit and book a session at Mallory Park again....!

I still haven't worked out what to do about some sort of scoop in the bonnet. However, in the absence

of any sort of decision I did at least cut a hole so as to unblock the air filter a little. I suppose as a short

term issue I might just put some mesh over this hole.

I still haven't worked out what to do about some sort of scoop in the bonnet. However, in the absence

of any sort of decision I did at least cut a hole so as to unblock the air filter a little. I suppose as a short

term issue I might just put some mesh over this hole.

I've booked a couple of outings for this coming weekend, so I need to make sure the car's all together

OK. I'm going to a Bookatrack track day at Croft on Saturday and down to North Weald airfield on Sunday for a "setip

and handling day", whatever that is.

I've booked a couple of outings for this coming weekend, so I need to make sure the car's all together

OK. I'm going to a Bookatrack track day at Croft on Saturday and down to North Weald airfield on Sunday for a "setip

and handling day", whatever that is.

I had ordered some new shorter springs from Demon Tweeks and they arrived today. Fitting them was pretty easy and after that I set into an orgy of setting up, again. I checked the ride heights, front and rear camber and rear toe. The front toe was checked at the weekend. I certainly seem to be getting the car a bit closer to what is the proper set up, at least statically in the garage.

I've borrowed some corner weight scales (four scales, one for each wheel) from a cam7er and I got the car up onto those. I then spent a frustrating few hours twiddling spring platforms trying to get some semblence of evenness into things. It's easy enough to get the front even but the rear is just about impossible, mainly owing to the fat lump sitting in the driver's seat. Perhaps if I was to chop off a leg it would make things easier?

Actually, one advantage of the shorter springs is that they're about 1kg lighter than the longer ones. Makes you think I should have got 6" ones instead of 7".

It's been a weekend of driving around, and not a single photograph taken! Hence a few words instead.

It's been a weekend of driving around, and not a single photograph taken! Hence a few words instead.

The first thing was a trip to a trackday at Croft on Saturday. The big problem with this was getting up at 4am in order to get there on time! We left Cambridge as the sun was coming up under a blue sky. Somewhere around Peterborough we seemed to go under a black cloud umbrella which stayed with us all the way to Darlington.

Great! Another wet circuit. Luckily this one seemed to have a bit more run-off than Mallory so hopefully I wouldn't end up in the barriers again. The day was sessioned so we then settled into a schedule of 20 mins running followed by 40 mins back in the paddock. The weather got steadily better throughout the day, and the last two sessions were brilliant. However, at the start of the day it was a real skating rink and I had a few moments. Most notably locking up the brakes everywhere (memories of Mallory) but most particularly into Tower which caused a couple of spins onto the grass. There was also a moment locking up into Sunny Out which entailed a trip down the escape road. Luckily I was able to recover from all these easily enough, especially as the reverse unit had stopped working in the paddock. The lever was flapping around ominously, meaning something must have actually bust.

It has to be said that in the wet the car was a real handful, I seemed to have very little feel for when the brakes were locking up. It may be that I just have to develop the sensitivity and, in retrospect, I was getting better at it. I was certainly bottling out of lots of things though. In particular, the run down into Clervaux was taken with rather less bravery than would have been possible, just because there was just not enough run-off there. As it was I was flat in fifth past the pits and just about into sixth so I must have been making a decent rate. (I really ought to work out what "flat in fifth" amounts to.

I'm still concerned about the banging from the transmission, but unsure what to do about it.

Sunday it was off to North Weald for a Fisher "set up and handling" day. This was just the time to charge around on some large bits of concrete and try twiddling various things on the car. I spent a while trying to sort out the brake balance which seemed to be too far to the front. As it was I wasn't about to lock the rear brakes at all at first. However, I adjusted the bias bar a bit, by moving the place the rear pushrod attached slightly, and then I could get either the fronts or rears to lock first. Problem was, all the accelerating and decelerating left me feeling rather queasy and I left quite a lot of rubber on the surface.

While I was there I also adjusted the throttle pedal slightly, so as to improve the heel and toe position.

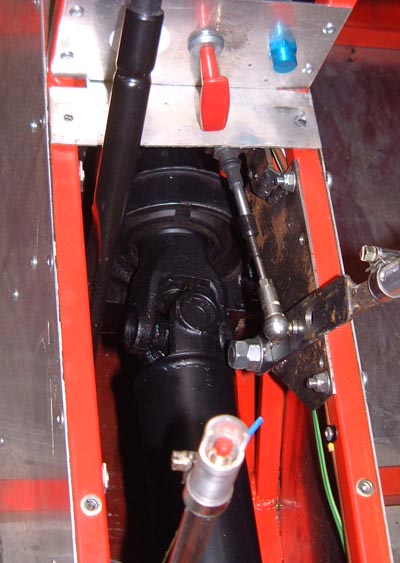

The big issue, though was the transmission noise. Both Martin Bell and Mark Fisher had a go driving the car and they both declared that it was worse than any other BEC that they had driven. One possibly culprit is the diff, although it's hard to see what it could be. There does seem to be some backlash in the diff, but there seems to be more elsewhere. Mark suggested that he could supply another diff and I could try that, to at least eliminate that. He also thought, although not understanding why, that moving the propshaft centre bearing might help a bit.

Having thought about it, I'll try moving the centre bearing a little, just to see if there's any effect. I'll also take the back plate off the diff, to try and see where the backlash that is there is coming from.

I did spend a whike charging around the few cones that they had set up at the airfield. However, it was exceptionally bumpy and consequently very hard to get any decent information out of it. However, it was good to get to the sort of situation where I could, for the first time really, actually start steering the car with the throttle. That is, there was one corner where it was a choice between armfuls of understeer or armfuls of oversteer depending on throttle position. I'm not sure, but wasn't convinced that the car was turning in as well as it could have done. I may try twiddling the front end setup slightly.

One final thing is that I got the entry information for the coming race at Lydden Hill. It's a very small circuit (Mark Fisher reckoned that I might not get out of 3rd gear!) and perhaps because of this there are two RGB grids, meaning that all the class C cars will be together. That should make it rather fun!

It's time to get the car ready for the next race this weekend. So, I got round

to starting a collection of small jobs.

It's time to get the car ready for the next race this weekend. So, I got round

to starting a collection of small jobs.

First up, I raised the prop shaft centre bearing mounting slightly, on the hope that this might affect the transmission banging. I actually went round to DH2's house this evening to have a look at how much backlash there was in diff. Surprisingly, if anything his has more movement than mine. It felt a little different though, presumably as he's got the Quaiffe ATB internals in his Freelander diff.

Whether moving the bearing will do any good remains to be seen.

I also fixed the electric reverse. It turned out that the engagement cable had

broken just by the control lever. Not sure why that should be, but I shortened the cable and got it all back together.

This time I tried to make the way the cable inner attached to the actuating lever a little more flexible, which

might make the chance of it breaking again rather lower.

I also fixed the electric reverse. It turned out that the engagement cable had

broken just by the control lever. Not sure why that should be, but I shortened the cable and got it all back together.

This time I tried to make the way the cable inner attached to the actuating lever a little more flexible, which

might make the chance of it breaking again rather lower.

Having got it all together again, it worked fine. What's more, it actually seemed a little easier to use, and felt less dodgy in operation. Hopefully, it'll stay together this time.

A couple of other little jobs have been done too. Firstly, I had an attempt at stopping the oil filter departing the engine using a large jubilee clip and a couple of tie-wraps.

The other thing relates to the speedo. Having gone to all the trouble of fitting it it didn't work at the weekend. On investigating it tonight I found that at some point I'd managed to trap the lead to the reed switch in the suspension mounting, meaning that the wires were mangled and permanently shorted together. I fixed this and it does seem to work now, although it remains to be seen how it works for real.

I took the morning off today to get the car completely prepped for the races this weekend. I say "completely" but there was something that crossed my mind a couple of days ago that I must do to the car. Presumably as a consequence of increasing senility I almost immediately forgot what it was. I've been racking my brain ever since to try and remember what it was without any luck. I'll probably remember when I'm half way round the first qualifying lap. :-(

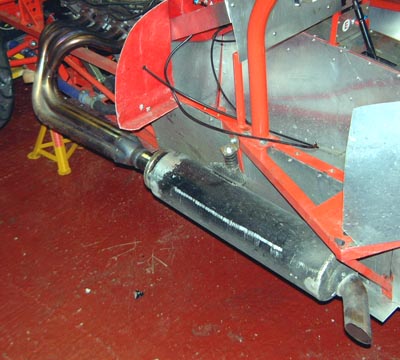

Anyway, one thing to do was to have a look at the exhaust again. I had noticed

that the tail pipe was bashing into the GRP again and wanted to check that everything was alright in here. With

the sidepod off it became apparent what the problem was in that the tail pipe had come loose slightly. I reattached

it, although I think I'll try and make some bracketry to weld the tail pipe to the main body of the can. I also

noticed that the bolts attaching the can to the flange at the front had come slightly loose, presumably as a result

of the heat cycling that they have to go through. I re-tightened them, with some threadlock this time. But, they'll

probably come loose again. One other thing I wanted to look at was the state of the valve spring support device

that I made a while ago. I was worried that welding to spring steel may not be too sensible. However, it all looked

fine. I guess I'll check it yet again after this coming weekend.

Anyway, one thing to do was to have a look at the exhaust again. I had noticed

that the tail pipe was bashing into the GRP again and wanted to check that everything was alright in here. With

the sidepod off it became apparent what the problem was in that the tail pipe had come loose slightly. I reattached

it, although I think I'll try and make some bracketry to weld the tail pipe to the main body of the can. I also

noticed that the bolts attaching the can to the flange at the front had come slightly loose, presumably as a result

of the heat cycling that they have to go through. I re-tightened them, with some threadlock this time. But, they'll

probably come loose again. One other thing I wanted to look at was the state of the valve spring support device

that I made a while ago. I was worried that welding to spring steel may not be too sensible. However, it all looked

fine. I guess I'll check it yet again after this coming weekend.

After that, I put everything back together again. As usual, I cleaned out all the junk that's jumped into the car from the track and even washed it!

So, now I'm ready for the trip to Lydden at the weekend. I've borrowed a friend's copy of the UK circuit guide so as to read up a little about the track. However, I'm still going to be driving blind really. I must admit to being really nervous again. To the extent that I wonder why I'm doing this to myself. Hopefully, this weekend will be fun.