There's been rather a long time since the last update, sorry about that but I've had work to do. Unfortunately

not very much of it on the car. Still I have made some fragments of progress, but I'l really starting to feel the

pressure now.

There's been rather a long time since the last update, sorry about that but I've had work to do. Unfortunately

not very much of it on the car. Still I have made some fragments of progress, but I'l really starting to feel the

pressure now.

I actually got the entry forms for this year's races the other day and I promptly sent it back with all the races ticked. Whether I actually make them or not is another question. What I do keep thinking though is that I ought to start thinking about setting myself some achievable goals for the season. I have no idea what they should be though.

Anyway, back with the car it was on with the suspension and I finished off putting the front suspension together, apart from tightening everything up, re-aligning it and rebleeding the brakes. With a view to the last of those I bought a large 5 ltr container of DOT4 fluid, reckoned to be fine for these cars, so I don't have to worry about having enough all year. Obviously, though, I need to fit the rear brakes and all the brakes lines before actually bleeding them.

However,

on getting to the rear suspension I struck a problem in that the new rear upper wishbones don't fit!

However,

on getting to the rear suspension I struck a problem in that the new rear upper wishbones don't fit!

I really should have realised this before making the wishbones but the rear inner mounting (at the upper right of the photo) is constructed in such a way that the tubes bash into the chassis, which is not really very clever! The problem really is that when using the suspension bushes the wishbone itself can be a bit more tight up to the bush, the rod end bearing inevitably sticks out a bit.

So, after a bit more thought I realised that the diagonal tube would have to approach the rod end bearing from the side, so as to frighten it into fitting properly.

In order to be sure this bit was going to fit properly, I made a test piece with a bit of wishbone

tubing and a rod end and it's mounting bush, as in the photo. This seemed to show that it was going to fit this

way.

In order to be sure this bit was going to fit properly, I made a test piece with a bit of wishbone

tubing and a rod end and it's mounting bush, as in the photo. This seemed to show that it was going to fit this

way.

So, I redid the CAD model and made a new jig and made a new wishbone.

I've

also seen a kosher Fisher one of these now and they do much the same thing to get to the rear inner mountings which

means I'm not being completely daft. The Fisher ones also mount the outer rod end bearing in a bush that's tilted

with respect to the plane of the wishbone itself. However, the measurements I've done seem to show that this isn't

necessary so I'm trying to avoid it at the moment. I do, though, have a horrible feeling that I may need to make

yet another pair of these which will be a real pain.

I've

also seen a kosher Fisher one of these now and they do much the same thing to get to the rear inner mountings which

means I'm not being completely daft. The Fisher ones also mount the outer rod end bearing in a bush that's tilted

with respect to the plane of the wishbone itself. However, the measurements I've done seem to show that this isn't

necessary so I'm trying to avoid it at the moment. I do, though, have a horrible feeling that I may need to make

yet another pair of these which will be a real pain.

This photo is of these version 2 wishbones which have had a single coat of Hammerite, hence the blotchyness. I'll have another go at them tomorrow.

So, with progress stalled on the suspension I decided to at least do one other little job. I'd noticed

over the closed season that the steering column seemed rather wobbly and on investigating noticed that the plastic

bush around the column (which I think is the standard Ford part) seemed very duff. So, I ordered a new one and

this is what the old one looked like when I got it off.

So, with progress stalled on the suspension I decided to at least do one other little job. I'd noticed

over the closed season that the steering column seemed rather wobbly and on investigating noticed that the plastic

bush around the column (which I think is the standard Ford part) seemed very duff. So, I ordered a new one and

this is what the old one looked like when I got it off.

I suspect that this is either just wear and tear or it's a hangover from the Donington crash, which certainly thumped the steering column about pretty feasomely.

So, I fitted the new one and it made things much better. Oddly, in the process of taking off the existing one I found the bolt that clamps the device that clamps the lower steering column to the upper column in two pieces. At some point in the last couple of months I must have tightened it up rather too vigorously. As it was, the head of the bolt had fallen off and landed on the inside of the undertray (so it must have happened quite recently). Seems very odd. I wonder if the cold weather we've had recently has caused it to shrink slightly and break off the head?

Hopefully I can finish off the suspension in the next few days. I need a couple of minor bits to finish off the rear lower wishbones and I thought they were going to be in the post from Rally Design when I got home today. There certainly was a package from Rally Design but it was a fusebox, which I didn't order. I guess they must have got my order mixed up with someone else. I shall phone them and berate them tomorrow. Odd because this is the second thing they've delivered wrong in the last couple of weeks and they're normally a really reliable supplier.

Bit late again, I'm afraid and this is probably the last update for a while as I'm away for a week

skiing next week. I'm also catching up on a lot of things. One of the main ones was really finally getting the

suspension together, although I can see there's going to be a huge amount of setting up to get everything pointing

in the right direction.

Bit late again, I'm afraid and this is probably the last update for a while as I'm away for a week

skiing next week. I'm also catching up on a lot of things. One of the main ones was really finally getting the

suspension together, although I can see there's going to be a huge amount of setting up to get everything pointing

in the right direction.

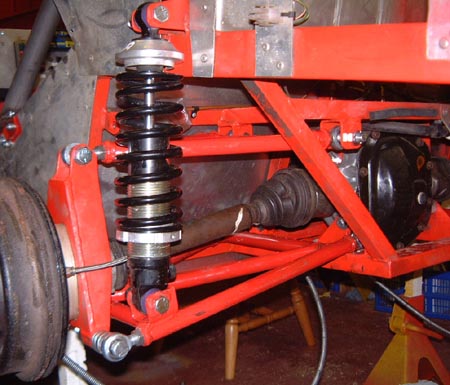

This photo is of the complete rear suspension. I'm still a bit wary that I've got the articulation of the top wishbone right but the only thing I can think of doing is getting it all together and jumping up and down on it.

(You can also see that I still haven't got all the grot off it. There always seems to be another patch of it...)

With

the rear suspension on I could now refit the fuel tank which just went straight back in. I realised that it does

have some fuel in it, which may well be useful in a couple of weeks, assuming it hasn't goen off completely over

the winter.

With

the rear suspension on I could now refit the fuel tank which just went straight back in. I realised that it does

have some fuel in it, which may well be useful in a couple of weeks, assuming it hasn't goen off completely over

the winter.

It now seemed to be the right time to put the bodywork back on. The right hand sidepod was easy, although it needed cutting around the roll cage which wasn't on last time I did this. I lined the left hand sidepod with a combination of heat insulation stuff (around the silencer) and ordinary kichen aluminium foil. After the problems I had with nearly setting fire to this stuff before I'm a bit wary about the sidepod but I suspect that the huge holes in the outside of it will actually do what I need to keep it coolish anyway.

Continuing with the bodywork theme I refitted the tub which was easy enough after I realised (it did

take me some time) that I needed to relieve it a bit around the right hand side support tube. I always realised

that this was probably going to be the case but seemed to manage to forget it for a while.

Continuing with the bodywork theme I refitted the tub which was easy enough after I realised (it did

take me some time) that I needed to relieve it a bit around the right hand side support tube. I always realised

that this was probably going to be the case but seemed to manage to forget it for a while.

However, once I put this cutout in the tub it fitted fine. In fact, this bit was good as all of a sudden it started looking like a real car again. I must admit that I've found fitting this bodywork much easier than the last time, I guess that's just experience, both with GRP bodywork in general and the Fury in particular. I remember the trouble I had with the Westfield bodywork which just seems ridiculously trivial in retrospect as it essentially just fitted.

One advantage of the new cage is that it isn't jammed right up against the tub on account of it being sited a few cms further forward.

That

really brings me back to today, when I spent the evening in the garage fitting the bonnet. As always, this is the

trickiest bit due to the hinges. I did actually consider losing the hinge frame and fastening the whole thing on

with Dzus fasteners but I really don't think I have time for such niceties.

That

really brings me back to today, when I spent the evening in the garage fitting the bonnet. As always, this is the

trickiest bit due to the hinges. I did actually consider losing the hinge frame and fastening the whole thing on

with Dzus fasteners but I really don't think I have time for such niceties.

Next thing will be to fit the new scoop to this bonnet.

I've also noticed that there's a bit of room, with the way that this bonnet is fitted, to move the radiator up by a couple of cm. That's probably a good idea as it does get rather bashed up with it is. Again, though, this can wait until the car's essentially back together before it gets in the way of just stopping me making the first race.

Well, after a week's skiing I'm back home and not too broken. Hence, it's time

to get on and get this thing working. First up, as I said, is to fit the bonnet scoop, to the new bonnet. So, I

marked it up, cut a big hole in the bonnet, and bonded the scoop in. It now looks like the photo here.

Well, after a week's skiing I'm back home and not too broken. Hence, it's time

to get on and get this thing working. First up, as I said, is to fit the bonnet scoop, to the new bonnet. So, I

marked it up, cut a big hole in the bonnet, and bonded the scoop in. It now looks like the photo here.

I'll need to do a bit of filling and rubbing down but hopefully not too much as I've managed to fit it fairly neatly.

With that done, I decided it was time for a major milestone. So, I reconnected the cooling system, filled it with water and filled the sump with (yet more) expensive oil.

After taking the plugs out I churned it around for a time (it always takes ages with Fireblades) until I saw some oil pressure. At last I got there, miraculously without flattening the battery which has just been sitting there all winter doing absolutely nothing. A lot of people use battery conditioners (sort of trickle charging things) but I've never bothered.

Then I fitted the new Iridium plugs that I got from Andy Bates. These are quite odd in

that the central electrode is really narrow, very different from a normal plug. The photo shows a new and old plug

so you can see the difference.

Then I fitted the new Iridium plugs that I got from Andy Bates. These are quite odd in

that the central electrode is really narrow, very different from a normal plug. The photo shows a new and old plug

so you can see the difference.

So, I put the plugs in, connected everything up, turned on the ignition (the little lights came on), turned on the fuel pump (the little light came on but the pump didn't go tuk-a-tuk-a-tuk).

Hmmm, that's not right, I thought.

So, I started checking that there was fuel in the tank (there was), there wasn't an airlock (there wasn't) there was electicity at the pump (there was). Hmm, the only think I could think of was that the pump had siezed up over the winter. So, I hit with a hammer and tried again. Still silence.

I found a bigger hammer and hit it with that. Still silence.

Ho hum. I took it out and banged it up and down on the bench, all the time thinking that I was clever enough to have bought a spare pump off EBay a while ago, and that that one had probably siezed up too. I connected the severely chastised (and, I hoped, chastened) pump back up and this time it chuntered happily.

I connecged everything back up again, checked that I still had oil pressure

and tried starting it. It burst into life immediately which was gratifying.

I connecged everything back up again, checked that I still had oil pressure

and tried starting it. It burst into life immediately which was gratifying.

There it is in the photo, trundling away. Admittedly that isn't immediately obvious from a still photo but you'll have to believe me.

I ran it for a while just to check that the temperatures came up properly, which they did. I didn't want to leave it just idling for too long though as it's just been rebuilt. Hopefully, in a while it can actually move the car.

Next thing was to fit the various lights to the car. This took much longer than it should but I eventually ended up with all four corners having lights in them. What's more, they worked. Well, they did after I dried them off as they've been sitting outside in the old bodywork for months.

The one slight problem was that I got a bit carried away and drilled the hole in the back

panel for one of the lights in the wrong place in that the light unit bashed into the rear of the chassis.

The one slight problem was that I got a bit carried away and drilled the hole in the back

panel for one of the lights in the wrong place in that the light unit bashed into the rear of the chassis.

Dooooh....

So, I had to make another hole and patch up the existing one. First of all using some tank tape and later on with some resin and matting. Anthea thought this was a hoot as the brand new bodywork was already held together with tank tape. Personally, I'm not convinced about the hilarity of it.