Things now seem to be slowly progressing towards the start of the season. Anthea and I went to the annual 750 motor club presentations dinner yesterday and had a great time. I wasn't impressed by the parsimonious attendance of RGBers though. The top 3 awards had no-one there to accept them.

Last week, I took the car up to Tony Law Exhausts in Leeds to get it a new exhaust

system. This should release a bit more power from the engine, at least with the addition of some different carburettor

jets and needles. It was fascinating watching the Tony Law staff work on their exhausts in that everything

is done by hand. All the forming of the tubing, and you see from the photo that that is fairly complex is done

by heating, bending by hand, and hammering. Real craftmanship...

Last week, I took the car up to Tony Law Exhausts in Leeds to get it a new exhaust

system. This should release a bit more power from the engine, at least with the addition of some different carburettor

jets and needles. It was fascinating watching the Tony Law staff work on their exhausts in that everything

is done by hand. All the forming of the tubing, and you see from the photo that that is fairly complex is done

by heating, bending by hand, and hammering. Real craftmanship...

With the new exhaust the car sounds a little different, although I clearly haven't tried it in any sort of anger.

With the season creeping up I need to get on with the rest of things on the to-do list.

One of these is to get the bonnet scoop finished. I think I've decided that I'm going to have to spray it anyway

and that makes the process of fitting it to the car less critical than it was. So, I marked up the bonnet and,

after a re-read the regulations again to make sure that this was indeed sensible, I cut a rather large hole in

some characteristically poorly made GRP. (Just like the old red bonnet, this one has a layer of gelcoat that's

about 4 times the thickness of the glass/resin layer.)

With the season creeping up I need to get on with the rest of things on the to-do list.

One of these is to get the bonnet scoop finished. I think I've decided that I'm going to have to spray it anyway

and that makes the process of fitting it to the car less critical than it was. So, I marked up the bonnet and,

after a re-read the regulations again to make sure that this was indeed sensible, I cut a rather large hole in

some characteristically poorly made GRP. (Just like the old red bonnet, this one has a layer of gelcoat that's

about 4 times the thickness of the glass/resin layer.)

I then positioned the scoop in place and positioned it with the fastener of

choice of the racing community, gaffa tape. This was actually amazingly difficult to do as the scoop kept falling

in and I had to go round and find it again.

I then positioned the scoop in place and positioned it with the fastener of

choice of the racing community, gaffa tape. This was actually amazingly difficult to do as the scoop kept falling

in and I had to go round and find it again.

Lastly, I used yet more matting and resin to bond the scoop to the bonnet. In fact, as I write this

resin hasn't gone completely hard yet. When it does I'll clean it up a bit, remove the gaffa tape and look at using

some filler to clean up the appearance on the top.

Lastly, I used yet more matting and resin to bond the scoop to the bonnet. In fact, as I write this

resin hasn't gone completely hard yet. When it does I'll clean it up a bit, remove the gaffa tape and look at using

some filler to clean up the appearance on the top.

I shall then have to find some suitable paint. I did wonder about trying to paint it red to match the rear bodywork, but that sounds awfully naff really...

Still feeling energised I finished (at last) fitting the bonnet scoop by bodging around the gap between

it and the bonnet with some filler and then rubbing it down with piles of different grades of wet and dry, in the

approved manner. (That's why this photo is sort of glisteney as it's still wet!)

Still feeling energised I finished (at last) fitting the bonnet scoop by bodging around the gap between

it and the bonnet with some filler and then rubbing it down with piles of different grades of wet and dry, in the

approved manner. (That's why this photo is sort of glisteney as it's still wet!)

All I need to do now is to find something to spray it with so as to cover up the exposed fillet of filler around the bottom of it.

It's taken ages to make this scoop but I', moderately happy with my first ever attempt at making a complex moulded shape with GRP. Next time, I'll spend a lot more time making the mould but this one does work and, as it's a race car, who's going to see the slightly naff finish anyway.

I also managed to knock a couple of items off the to-do list. There's still loads there though.

Slow progress this weekend. I spent all of Saturday taking part in a shoot for a TV programme that's being made about getting a car ready for RGB and racing it therein. It will be shown on Discovery Home and Leisure later this year. Whether you'll actually see me is any guess. In summary I sent Saturday getting cold in another bloke's shed. This wasn't much change from getting cold at home as our boiler's packed up and we're waiting for the "but that bit never fails" part to come in.

All the same, I needed to press on with the to-do list. A few

days ago I ordered some new shoes for the rear brakes so it was time to fit them. Of course, fitting drum brakes

shoes always takes a thousand times as long as you would think it should, although of course the second side took

me about a tenth of the time to do the first one.

All the same, I needed to press on with the to-do list. A few

days ago I ordered some new shoes for the rear brakes so it was time to fit them. Of course, fitting drum brakes

shoes always takes a thousand times as long as you would think it should, although of course the second side took

me about a tenth of the time to do the first one.

I also took the opportunity to re-bleed the brakes properly. To do the rears correctly you really need to loosen the backplate and rotate it so that the slave cylinder is at the top, as in the photo here. Of course, that all takes more time. I wonder why the brakes are fitting with the backplate in that position? I might be so that the upright can be narrower that way, although it would be odd that there's that much in it.

After that I moved to front of the car and replaced the pads in the front brakes. This time I'm fitting some Mintex 1155 pads, instead of the 1144s that I had fitted before. This is an experiment to see how they work. Of course, as they're more expensive than the 1144s they're bound to be much better.

Finally, I spent a while setting up the pedals rather better so that I could heel-and-toe properly. After some thought I think I now have enough space, as a result of moving the pedals, to fit a heel rest so as to move my heels a little back from the pedals. I think I've worked out the best position for it but I really need some ally angle to make it properly so with luck I'll be able to go and get that tomorrow.

I've been slowly pressing over the last few days, although I've not updated this site. I'm really concentrating

now on getting the car together properly for some testing. It would also be nice to get the trailer off the drive

and into the garage as that means the drive is easier to get at.

I've been slowly pressing over the last few days, although I've not updated this site. I'm really concentrating

now on getting the car together properly for some testing. It would also be nice to get the trailer off the drive

and into the garage as that means the drive is easier to get at.

The main thing I wanted to do next was to get another seat made. The first job was to make a rest for my heels. As I've managed to make a little more leg room in the car it seemed reasonable to "sacrifice" some of this to the advantages of getting my feet at a slightly more sensible angle. Hence this piece of aluminium rivetted just in front of the pedals.

(For some reason the camer doesn't like the red powder coating/hammerite down here and things look really horrible in photos compared to what they look like in real life.)

With that done it was time to get on with making a seat. I think I'm now getting rather

better at doing this (my first attempts were very frustrating and I made a large number of useless seats) as result

of discovering two things. First of all you can make a large plastic bag that still contains the foam by gaffa

taping two smaller bags together. Mind you, someone told me that it was possible to buy wheelie bin bags and that

would probably be OK anyway.

With that done it was time to get on with making a seat. I think I'm now getting rather

better at doing this (my first attempts were very frustrating and I made a large number of useless seats) as result

of discovering two things. First of all you can make a large plastic bag that still contains the foam by gaffa

taping two smaller bags together. Mind you, someone told me that it was possible to buy wheelie bin bags and that

would probably be OK anyway.

The second issue is that it isn't necessary to get it right first time. It is possible to make part of the seat and then either put the foam into another bag or to pull the bag away from the foam (it seems to be the one thing that the foam doesn't stick to too well) and add some more. This all means that you can have a bag big enough and work up to the having the right amount of foam without running the risk of blocking off the garage.

The photo here shows a doubled up bin bag in position before adding some foam. Note, by the way, that I've blocked up the depressions in the side of the chassis with some cardboard as otherwise the foam expands into that space and makes the seat completely impossible to remove. The lap straps of my harness are also in position as that means they'll make their own holes in the seat meaning that less foam will have to be chopped up later on.

Just to show how manky the seat can be in the early stages, this is the internals of that

bag after the first batch of foam (amounting to about 900ml unexpanded) had been added.

Just to show how manky the seat can be in the early stages, this is the internals of that

bag after the first batch of foam (amounting to about 900ml unexpanded) had been added.

You can see the indentation of my legs at the front and how the fact that I've sat on it has made the thickness of the bottom of the seat essentially zero.

After a couple of more goes I ended up with something pretty reasonable.

You do need to cover up the foam as without that it would just fall to bits. (It's hard and abrades easily meaning that tiny pieces fall off all the time. In fact, they get walked over the house...)

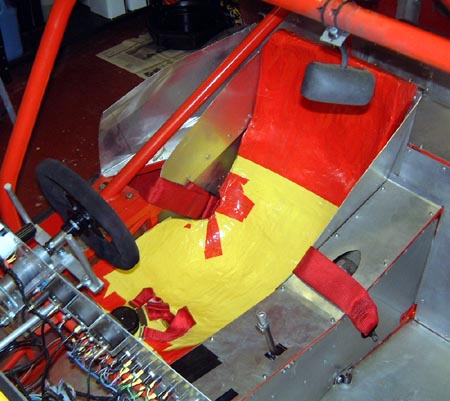

I decided, yet again, to use the traditional covering with gaffa tape. Last time I used black tape

but I don't have enough of that left this time. What I do have is some red and some yellow. I decided to go for

a mixture of the two, in homage to the car's colour scheme. Hence, I ended up with this thing here.

I decided, yet again, to use the traditional covering with gaffa tape. Last time I used black tape

but I don't have enough of that left this time. What I do have is some red and some yellow. I decided to go for

a mixture of the two, in homage to the car's colour scheme. Hence, I ended up with this thing here.

Yes, I know there isn't neat line between the two, but it's artistic, innit?

The problem with getting to this point is that you end you end up with huge amounts of bits of foam all over the place which stick to everything, including you, in an alarming fashion. The reason for all the bits is that you have to chop the moulding up quite a lot as the idea is always to make it overlarge and cut it down.

After that I put it in the car, sat in in a worked out where the crotch straps had to go

and then cut out some holes that I could fit the straps through. That made even more mess, of course, but I ended

up with something that seems pretty reasonable, and is much more robust that the one I used last season. Of course,

I need to actually try this one first...

After that I put it in the car, sat in in a worked out where the crotch straps had to go

and then cut out some holes that I could fit the straps through. That made even more mess, of course, but I ended

up with something that seems pretty reasonable, and is much more robust that the one I used last season. Of course,

I need to actually try this one first...

What I did notice with all the leaping in and out of the car was that the newly bled (yet again) brakes are really nice and hard. That's good.

I tried driving the car forwards by 3 feet in the garage just to see if it worked. However, there was a horrible noise coming from the area of the diff which was worrying. However, on investigation it turned out that it was coming from the reversing unit which I'd re-fitted slightly too close to the diff ring gear. It didn't take long to take off the inspection panel just to the left of the seat and adjust it.

So, I'm now very close to getting the car out again. There are still things on the to-do list but it's getting there. Apart from a couple of necessary ones, such as fitting a new catch tank, (aka Coke bottle) then the car is essentially ready for some sort of testing.

There is a chance of doing some testing later this week at Snetterton. However, the weather forecast may just be for snow and pestilation so it might be worth giving it a miss.

Well, I didn't get to Snetterton. The bloke I was going with emailed me to say that they had cancelled the test, probably a good thing really as the weather was pretty awful.

So, I got with a few other things on the list. I've been jumping in and out of the car a lot recently and at first I wasn't too sure about the new seat and thinking that I needed to make another one. One of the issues with foam seats is that you can't move them about at all. If you think you'd like to sit in a slightly different position then you really have to just make another seat. One slight problem with the new seat is that it goes a bit further forward and this precludes using the chassis member across the front of the seat for standing on when I get in and out of the car. (I don't really like to stand on the seat, you see.) This means that it's a bit more difficult to get in an out, but I guess I'll get used to it.

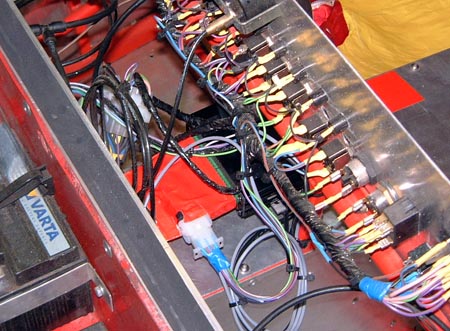

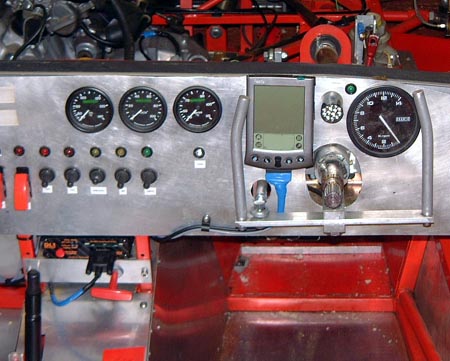

I wanted to mount the Palm on the dash in some way, although I haven't really worked out

how to weather-seal it. (Although, cling film seems a possibility.) So, in preparation for that, I checked that

it was working properly and discovered that it wasn't. To but a long story short I discovered a fault on the speed

sensor frequency divider that I made a while ago. The Schmitt trigger on the input side had failed and this is

actually the second time that this has happened. One possibility for this is that excessive voltage excursions

on the input are frying the chip so I replaced the dead device and added some clamping diodes to the input. I'll

just have to see how it goes to see if there's any change.

I wanted to mount the Palm on the dash in some way, although I haven't really worked out

how to weather-seal it. (Although, cling film seems a possibility.) So, in preparation for that, I checked that

it was working properly and discovered that it wasn't. To but a long story short I discovered a fault on the speed

sensor frequency divider that I made a while ago. The Schmitt trigger on the input side had failed and this is

actually the second time that this has happened. One possibility for this is that excessive voltage excursions

on the input are frying the chip so I replaced the dead device and added some clamping diodes to the input. I'll

just have to see how it goes to see if there's any change.

After that I put some tank tape around the electronics as a partial attempt at sealing

it up and tidied up the wiring. You can just about see the adapter board inside its red coat in the photo above.

I also fitting the Palm to the dash using some velcro, here's the end result.

After that I put some tank tape around the electronics as a partial attempt at sealing

it up and tidied up the wiring. You can just about see the adapter board inside its red coat in the photo above.

I also fitting the Palm to the dash using some velcro, here's the end result.

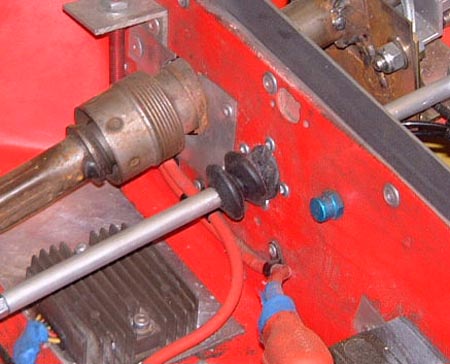

Next job was to seal up the hole in the scuttle around the paddle gearchange

selector rod. I cannibalised an old brake master cylinder and used the rubber boot off it to fit pretty snugly

around the rod. I hope this is OK for the scrutineers.

Next job was to seal up the hole in the scuttle around the paddle gearchange

selector rod. I cannibalised an old brake master cylinder and used the rubber boot off it to fit pretty snugly

around the rod. I hope this is OK for the scrutineers.

Finally, for today, I moved the in-cockpit extinguisher outlet to point at me, rather than the gearshift paddle.

I think one of the major things I need to look at next is getting the car set up a bit better. It seems to be a smidgeon too low at the moment.

Today I fitted a new catch tank. In fact, I thought of a clever tweak and instead of using

a Coke bottle, which is obviously heavy, I use a 7-up one which, as you can tell from the name, will be a lot lighter.

Today I fitted a new catch tank. In fact, I thought of a clever tweak and instead of using

a Coke bottle, which is obviously heavy, I use a 7-up one which, as you can tell from the name, will be a lot lighter.

With that done I moved onto starting the set-up of the car again. As I suspected

it was a little low. The chassis itself was fine but the sump was a bit too low, although only at the front. I

decided to raise the engine slightly so as to allow me to actually drop the chassis a bit. If nothing else this

will allow me to get the bottom wishbones in the front suspension just about horizontal which is supposedly where

they are best set. I've never actually managed to get them down there due to the sump on the engine being too low.

With that done I moved onto starting the set-up of the car again. As I suspected

it was a little low. The chassis itself was fine but the sump was a bit too low, although only at the front. I

decided to raise the engine slightly so as to allow me to actually drop the chassis a bit. If nothing else this

will allow me to get the bottom wishbones in the front suspension just about horizontal which is supposedly where

they are best set. I've never actually managed to get them down there due to the sump on the engine being too low.

I raised the engine a while ago by putting a block of aluminium under each of the front mounts. Some time after that I turned around the rear mount so lifting the back of the engine a bit. This time, I put some more aluminium under the front mounts and put some washers under the rear mount. The bottom of the sump is now pretty much exactly level with the bottom of the chassis. If nothing else, if I do ever get round to flat-bottoming the car this will make it a bit easier to do.

With that done I did manage to lower the car a bit more. However, I need to corner-weight the car again. Luckily there are a local cam7 set of car scales. However, I'll need to borrow them from where they are the moment which will take a couple of days. In the meantime I'll check the camber and toe settings. I have been wondering about making a toe-gauge of some form and now might be the time to do it.